by Kelvin F.Long

Centauri Dreams readers will know Kelvin Long as the Chief Editor for the Journal of the British Interplanetary Society, but the résumé hardly stops there. He is also the Deputy Chair of the BIS Technical Committee and a member of the governing council. Long is the co-founder of Project Icarus, co-founder of the non-profit Icarus Interstellar (formerly serving as the Vice President European Operations) and is the co-founder of the pending Institute for Interstellar Studies. He is the managing Director of the aerospace company Stellar Engines Ltd. Here Kelvin begins a two-part article (to be completed on Monday) highlighting the British Interplanetary Society and its numerous contributions to spaceflight concepts both interplanetary and interstellar.

Liverpool is a unique location in British history. Not just because of the Beatles or Olaf Stapledon, but because this is where the British Interplanetary Society (BIS) was founded in 1933 by a Cheshire-born engineer, Philip E.Cleator. Impressed with the rocketry efforts in the US and Germany, he took the initiative to form a UK based rocket society and he published his article “The Possibilities of Interplanetary Travel” in Chambers Journal in January 1933. This was subsequently picked up by the Editor of the Liverpool Echo and eventually by the national press in the form of the Daily Express. This led to a front page feature and the gathering of a small collection of local people at his home.

The decision was then made to set up the British Interplanetary Society. The inaugural meeting of the society took place at the office of H.C.Binns on the second floor of No.81 Dale Street, Liverpool, on Friday 13th October 1933. It was not until the end of 1945 that the articles of the reformed BIS were drafted (the society was suspended during the war) and the society registered as a limited company. It was in 1936 that the London section was formed and this eventually became the main headquarters the following year. For the record, the Journal of the British Interplanetary Society was founded in 1934 and is the oldest astronautical journal in the world. The society’s popular space magazine Spaceflight (now edited by David Baker) was founded in 1956 (a year before Sputnik 1), and remains at least one of the oldest space magazines still in existence (today the BIS also publishes the space history journal Space Chronicles (1980), edited by John Becklake, and the science fiction based e-magazine Odyssey (2011), edited by Mark Stewart.

Image: Current headquarters of the British Interplanetary Society at 27/29 South Lambeth Road, London. Credit: Colin Philp.

The society grew from those early foundations and some of the earlier members included people like Arthur C. Clarke, Les Shepherd, Eric Burgess, Ralph Smith, Harry Ross, Ken Gatland, Val Cleaver and later on Patrick Moore. For anyone who knows their space history, all of these people have had huge impacts on the development of space technology or in helping to communicate and advocate for the exploration of space. Clarke pioneered the idea of the telecommunications satellite as well as writing world class science fiction; Eric Burgess was the first to suggest to Carl Sagan that a message for ET could be included on the Pioneer spacecraft; Val Cleaver was the inventor of the British rocket engine that went into the Blue Streak missile; Gatland, Smith and Ross were all pioneers of rocketry, satellite payloads and space architectures; Les Shepherd was a pioneer of nuclear propulsion and eventually went on to be the president of the International Astronautical Federation (IAF), an organization that included the BIS as one of its founding members in 1951.

According to the Memorandum of Association:

“The objects for which the British Interplanetary Society is established are to promote the advancement of knowledge and the spread of education and particularly to promote the advancement and dissemination of knowledge relating to the science, engineering and technology of Astronautics and to support and engage in research studies and to disseminate the useful results thereof and in furtherance thereof…to hold meetings, promote exhibitions, publish reports, make awards, medals or grants, to provide funds for educational and academic activities in furtherance of its objects”.

In order to understand the crucial role that the British Interplanetary Society has played in the history of space exploration, it’s worth looking at some examples from the society’s rich technical history.

The BIS Moonship

For years people had dreamed about visiting the Moon and some even wrote about it. Jules Verne originally wrote From the Earth to the Moon in 1865. This is a fascinating tale of a group of people who build an enormous space gun and launch themselves in a projectile spaceship all the way to the Moon. Verne had apparently done some calculations for the mission, although the particular method lacked the safety we have come to expect for man-rated vehicles – it is not likely the crew would have survived the trip. H.G.Wells made an interesting attempt at lunar flight in his 1901 story The First Men in the Moon. The vehicle would use a mysterious substance called “Cavorite” which would negate the force of gravity to effectively give the vehicle its required lift properties and allow a visit to the extraterrestrial civilization of insect-like creatures inhabiting the Moon known as the Selenites.

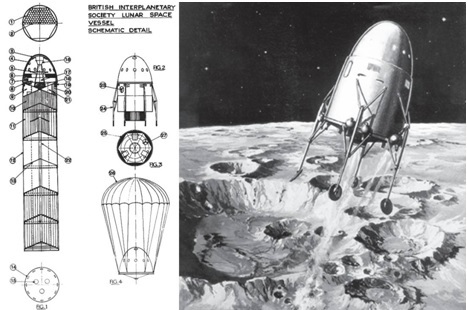

These were wonderful works of the imagination but could we come up with anything that resembled reality? So it was that in 1938, the BIS Technical Committee decided to go the full distance and produce a conceptual design of a vessel that would carry a crew of three safely to the Moon, permit them to land for a stay of fourteen days, and provide for a safe return to the Earth with a final payload of half a ton. The object of the exercise was to demonstrate that, within the capabilities of propellants that could be specified (at least theoretically) at the time, such a mission was not merely possible but would be economically viable – insofar as the vehicle lift-off mass from the Earth would be no more than one thousand tons. The conceptual design that resulted came to be known as the BIS Lunar Spaceship, and for all its flaws and misconceptions it must be regarded as one of the classical pioneering studies in the history of astronautics.

Image: BIS Moonship and Lander. Credit: British Interplanetary Society.

The mission proposed for the Lunar Spaceship would involve total velocity changes in excess of 16 km/s, a figure that would be significantly increased by certain losses. The best available propellants were not expected to achieve rocket motor efflux velocities of one quarter of that figure. This enormous disparity implied that, if one attempted to achieve the entire mission with a simple single-stage vessel, 99% or more of its initial lift-off mass would have to consist of the propellant. (In the more common parlance of rocketry this required a mass ratio exceeding 100.) The most enthusiastic proponents of space flight were at one with their critics in dismissing this as inconceivable. To circumvent the problems, the pioneers of astronautics invented the Step Rocket, in which the vessel consisted of a series of stages of diminishing size, fired in sequence. As each successive stage completed firing, its engines and other redundant structure would be discarded leaving the higher stages to continue the flight.

In this way it would be possible to obtain a high mass ratio without invoking the need to achieve impossible structural factors. Looked at in another way, the total velocity change required of the overall vessel would be shared between the stages. In this case, four equal stages would each need to contribute little more than 4 km/sec to the total velocity change. That would be possible with the performance of known propellants. The proportion of the stage mass taken up by propellant would assume a reasonable level (say, 75%, corresponding to a mass ratio of 4). However, a penalty would be incurred in the final payload, which would be reduced in inverse proportion to some number raised to the power of the number of stages. Optimistically, at the time, that number might have been taken as 10. Thus, with four stages, the final payload might be expected to be only one ten-thousandth of the lift-off mass. The nub of the argument of the more informed critics of such a lunar flight would have been that such a mission would probably have required as many as five stages, perhaps more, so that the initial vessel would have had to match an ocean liner in size to carry an ultimate payload of one ton. Such a mission could not be viable.

In 1919 Robert Goddard, in his classic paper “A Method of Reaching Extreme Altitudes”, went a stage further than the step rocket principle in suggesting a firing procedure that amounted to the continuous discarding of redundant structure. This procedure, in principle, could result in a significant improvement in payload ratio compared to the step rocket. The BIS, in its design concept, adopted a cellular construction that, in essence, conformed to Goddard’s suggestion.

The BIS Space Ship was described in the January 1939 Journal by H.E. Ross. The vessel was divided into six tiers (steps) of equal hexagonal cross-section and the six sections were made up of an array of tubes each consisting of separate rocket motors. Each of the lowest 5 steps was made up of 168 motors, intended to impart sufficient velocity to achieve escape from the Earth’s gravitation. The remaining stage consisted of 45 medium motors and 1200 smaller tubes intended to land the remainder of the vessel on the Moon, allow for subsequent escape from the latter (leaving redundant structure on the surface of our satellite), and for reduction in velocity prior to entering Earth’s atmosphere. Perhaps the most important lasting achievement of the Lunar Spaceship study, however, came from its conclusions regarding the landing upon, and lift-off from, the lunar surface. R.A. Smith developed the concept after World War II in an article – “Landing on an Airless World” – published in the August 1947 BIS Journal, accurately depicting the procedure that was to be adopted with the Apollo Lunar Excursion Module. The only notable difference between the two cases was, perhaps, that Smith’s design was more elegant than the actual LEM.

The Technical Committee decided that its activities should embrace an experimental programme to support its Lunar Spaceship concept. From the outset, it rejected the experimental “firing of free rockets” as valueless on account of their small scale and lack of control over the many parameters involved in such flights. It made no attempt, therefore, to emulate the VfR [the German Verein für Raumschiffahrt, or Society for Space Travel] or later American groups. The BIS workers considered that the development of rocket motors for their proposed lunar mission would have to proceed in stages, beginning with literature and experimental studies of possible propellants, followed by the design of chambers and nozzles on the best theoretical basis – the work of Sänger was cited as noteworthy in this respect.

The resulting motors and selected propellants would then be brought together in static proving stand firings in which all the variables could be systematically controlled and measured. The intention was correct and logical, but even the over-optimistic members of the Technical Committee were bound to note that such a program was far beyond their resources. Nevertheless, largely under the supervision of Janser, who was a research chemist, they embarked on the preliminary stages of the propellant survey hoping that eventually they would solicit sufficient support from public benefactors, convinced by the evidence emerging from the Lunar Spaceship study, to proceed with serious development. Undaunted, R.A. Smith designed a basic test stand that was actually constructed. Despite some shortcomings, the program of the Technical Committee was a laudable endeavor.

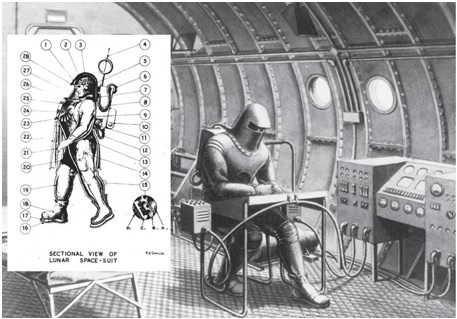

The BIS Space Suit

In a November 1949 symposium, Harry Ross presented a paper on the “Lunar Space-Suit”. Ross had examined the problem of a 68 kg lunar space suit (equivalent to 11 kg on the Moon) which could be worn for up to 12 hours, within the temperature range of 120 degrees to minus 150 degrees Celsius, representing night and day. The suit design was 4-ply, made up of a thin exterior skin of closely woven cloth. It had a 1 cm layer of cellular heat-resisting material (Kapok, wool, felt et cetera) and a 1-2 mm main airtight sheath of fabric-backed natural or synthetic rubber. It also had an interior lining of non-hygroscopic material, mainly for comfort and to manage contact between the rubber and skin and absorption of the water-vapor.

Image: The BIS Space Suit. Credit: British Interplanetary Society.

The exterior of the lunar space suit was to be a highly burnished metallic film, designed to reflect as much heat as possible. The chest and thigh areas were to be given an external matt-black finish to manage heat loss. Operation of the suit during the lunar day would require further cooling through the use of a low boiling liquid such as ammonia or water – which would vaporize to space through a thermostatic valve. The helmet was to be a light, rigid double-shell structure, with the inner a bright alloy metal and the outer a plastic with burnished metal coating. Lateral vision of 180 degrees was proposed with a minimal vertical extension in order to minimize heat gain or loss. A special glass to prevent heat and actinic ultraviolet rays would be employed. There would be further precautions, including providing the helmet with a shading peak and an external moveable visor made either of darkened glass or bright metal pierced with cross-slits in front of the eyes. The suit was to be a good fit to ensure maximum comfort and the shoulders would be internally padded.

Considerable thought went into the problem of air-conditioning, as discussed by Bob Parkinson in his book Interplanetary:

“Compressed (bottled) oxygen was regarded as simplest, and Ross recognized that a skin-tight suit with bottled oxygen flushing to waste might be sufficient, the weight of even a 12-hr supply not being excessive. However, a pure liquid oxygen supply was suggested, with the atmosphere maintained at about 160 mm Hg (21 kPa). The suit’s atmosphere was to be circulated through the conditioning units and throughout the dress by an electric fan-pump driven by the electric battery. Respired carbon dioxide was to be removed by chemical means – sodium peroxide being preferred because the reaction yielded oxygen, reducing the generous allowance of 0.78 litres per min by as much as 43% – as against, for example, sodium hydroxide, where there is no regain. The sodium peroxide would also absorb water, of which it was assumed the lungs and skin would yield some 108 gm/hr”.

The space suits that were eventually worn by the Project Apollo astronauts are a far cry from this original 1940s design. But the work started out by Harry Ross led to credible thinking on how humans could survive in a self-contained, mobile habitat. The original paper by Harry Ross is titled “Lunar Space Suit,” Journal of the British Interplanetary Society, Vol.9, No.1, pp.23-37, January 1950

Project Megaroc

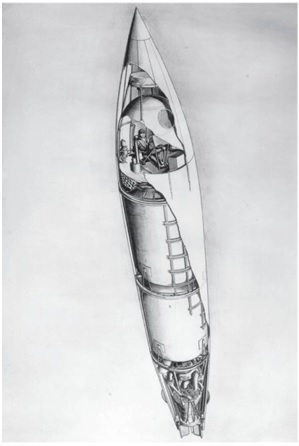

The “Megaroc” man-carrying rocket proposal had been put forward by R.A. Smith in 1946 after H.E. Ross observed that the V-2 was “nearly big enough to carry a man.” The objective was to provide manned ascents to a maximum of 304 km (one million feet). During flight, it was proposed that scientific observations could be made of the Earth and the Sun, that radio communication through the ionosphere could be tested, and that data should be collected on human performance over a wide range of g-conditions. The project was submitted to the Ministry of Supply on 23rd December 1946, but rejected. The proposal has remarkable similarities to the subsequent American Mercury project. Where differences do occur, they generally arise from the fact that Megaroc was much less ambitious, not being designed for orbital flight.

The Ross and Smith Megaroc was a modified, enlarged and strengthened V-2. The normal motor was retained but the tank diameter was increased and the end walls strengthened to accommodate enough propellant for 110 sec at full thrust, and a further 38 sec at constant acceleration. This brought the maximum hull diameter up to 2.18 m. The graphite efflux control vanes were retained, enlarged, and given the extra duty of imparting a slow stabilizing spin to the rocket. On the other hand, the big aerodynamic fins and associated controls were omitted, saving some 320 kg of weight. This was, indeed, one of the first big rocket designs in which aerodynamic fins were omitted – a feature not generally adopted in practice for another ten years.

Image: The BIS Project Megaroc. Credit: British Interplanetary Society.

The standard turbo-pump was retained but turned through 90°, rotating about the major axis of the rocket to prevent the turbine promoting tumbling after fuel cut-off. In place of the instrument bay and warhead there was a pressurized cabin, enclosed in a streamlined, jettisonable nose cone. This brought the overall length of the rocket up to 17.5 m. The launch weight was 21.2 tons. The cabin, with a return weight of 586 kg, had two large side-ports for access, observation and egress.

There was also a “strobo-periscope” (a modified form of the BIS’ pre-War coelosat, which was an experimental device to examine the possibilities of interstellar navigation) for rearward viewing after the rotating cabin had separated from the hull. Mercury’s one-ton double-walled titanium cabin started off with a topside escape hatch, two small ports and a periscope. However, the hatch was later more conveniently situated, like Megaroc’s, in the side of the cabin and arrangements were made for picture-window visibility. Megaroc’s observer was to wear a standard high-altitude g-suit, with its own air-conditioning unit and personal parachute. No other air-conditioning was proposed owing to the short duration of the flight. Although both used a cradle-type seat with integral controls, the Mercury cradle was fixed while Megaroc’s was counterbalanced and designed to tilt. The cabins of both rockets were attitude-stabilized by hydrogen peroxide jets, and both were fitted with automatic, manual and emergency controls, differing mainly in that the Megaroc was designed for a less hazardous mission.

Mercury’s cabin was provided with a heat shield against frictional heating upon re-entry to the atmosphere, retro-rockets and parachutes for braking and descent. Megaroc needed no special heat shield and relied on a reefing parachute ejected by spring flaps and a compressed air charge to provide constant drag irrespective of air-density and velocity of descent. Megaroc’s cabin was suitable for either sea or land impact and was fitted with a crumple skirt to absorb some of the shock and avoid bounce with a quick-release mechanism for the parachute. The maximum ascent acceleration imposed on the Megaroc observer was 3 g (for Mercury the figure was 9 g).

Megaroc would be launched from a tower inclined at an angle of 2° from the vertical with an initial acceleration of 9.8 m/sec2. Constant thrust would be maintained for 110 sec when the rocket would have reached 46,000 m, and the effective acceleration would have become about 20 m/s2. At this point the pilot would be experiencing 3 g, the limit at which it was thought that operational duties could be satisfactorily discharged. The pilot would actuate the fuel controls at this point to progressively reduce thrust and keep the g-meter reading constant. In case of emergency at any stage of the flight, relaxation of the pilot’s grip would switch the rocket from manual operation to automatic radio-telecontrol from the ground.

When the air-density had reduced to a point where drag was negligible, a pressure operated release mechanism would unlatch the nose-cone sections ready for jettisoning. At some subsequent moment the pilot would operate a compressed-air charge to drive the cabin and hull apart. This would also initiate operation of a delay mechanism for ejection of the hull-recovery parachute.

The control connections between cabin and hull would uncouple automatically on separation and the communication system would be switched from the four-dipole arrays arranged in blisters near the stem of the hull to arrays situated under the floor of the cabin. Cabin attitude and rate of spin would be controlled by hydrogen peroxide jets. It was thought that the pilot would therefore be able to carry out experiments with various values of g, down to zero, including free movement inside the cabin, and would be able to turn the cabin stern-down for re-entry into the atmosphere. The apex of the trajectory would be attained about 6 min 16 sec after launch and the cabin’s constant-drag parachute was to be ejected in descent at an altitude of about 113 km, the maximum deceleration imposed on the pilot being calculated as 3.3 g. The parachute would be fully extended on approaching touchdown, when it would be released to prevent the cabin from being dragged along.

It was appreciated that the Megaroc project would need to progress through a series of preliminary experiments to test the practicality of the design. For example, the modifications to the turbine and fuel control, and the endurance and reliability of the motor under the prolonged running conditions would need to be verified. The efficiency of other special innovations, such as the crumple skirt, variable-area parachutes and strobo-periscope were also to be tested. An operational mock-up of the cabin was proposed, to be suspended by a cable so that the pilot could be trained in control of orientation and spin. The pilot would also be trained in the telecontrol of an unmanned rocket and cabin assembly in free flight. Manned ascents to progressively increased altitudes were to be undertaken before attempting the maximum terminal altitude of over 1,000,000 ft (304 km).

End of part one. Part two follows on Monday.

I believe you are wrong about this one, too. The next generation of interplanetary craft will be propelled by ion drives, and at least some will be nuclear. Space reactors are a relatively mature technology, it will be revived in time.

Smaller spaceships may be shot directly into escape using conventional launch vehicles, larger ones will be assembled at LEO. LEO is the first stop out of the gravity well. It is mandatory if you want to minimize chemical propulsion. There is no better place to switch propulsion methods. Certainly not the moon.

Wrong. LEO is bound to become the key waystation between Earth surface and all other destinations. It is where space tugs will line up to refuel, be serviced, and push craft and payload launched with chemical rockets from the surface into higher orbits, using ion drives or sails. It is also currently the only place in space with a permanent human presence, and will remain so for quite a long time.

The moon will only start playing a role when it becomes possible and economical to establish largely self-sufficient industry on it. With mining, smelting, refining, the whole enchilada all the way to manufacturing. This is going to take a VERY long time, and it is possible that it is never going to happen, because asteroids are more suitable and accessible. In any case, the process will keep all those tugs at LEO extremely busy for centuries to come.