Imagine the kind of spaceship we’ll need as we begin to expand the human presence into the nearby Solar System. We’d like something completely reusable, a vessel able to carry people in relative comfort everywhere from Mars to Venus, and perhaps as far out as the asteroid belt, where tempting Ceres awaits. Capable of refueling using in situ resources, these are ships not crafted for a single, specific mission but able to operate on demand without entering a planetary atmosphere. Brian McConnell, working with Centauri Dreams regular Alex Tolley, has been thinking about just such a ship for some time now. A software/electrical engineer, pilot and technology entrepreneur based in San Francisco, Brian here explains the concept he and Alex have come up with, one that Alex treated in a previous entry in these pages. The advantages of their ‘spacecoach’ are legion and Brian also offers a sound way to begin testing the concept. The author can be reached at bsmcconnell@gmail.com.

by Brian McConnell

“What if a spacecraft, like a cell, was made mostly of water?”

That’s what Alexander Tolley and I asked when we were working on our paper for the Journal of the British Interplanetary Society, “A Reference Design For A Simple, Durable and Refuelable Interplanetary Spacecraft” [1]. The paper explored the idea of a crewed spacecraft that used water as propellant in combination with solar electric propulsion. We dubbed them spacecoaches, as a nod to the stagecoaches of the Old West. Alex also gave the concept an excellent fictional treatment in Spaceward Ho!, also published here on Centauri Dreams. We are currently finishing a book about spacecoaches, to be published by Springer this fall. Subscribe to spacecoach.org for updates about the book and spacecoaches in general.

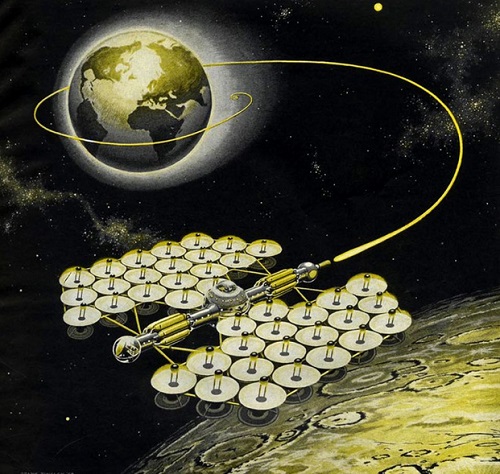

The idea of crewed solar electric spacecraft is hardly new. In 1954, Ernst Stuhlinger proposed a “sun-ship” powered by solar steam turbines and cesium ion drives [2,3]. Since then solar electric propulsion has been used in a wide variety of uncrewed craft. Meanwhile, the convergence of several technologies will make crewed solar electric vehicles feasible in the near future.

The core idea behind the spacecoach architecture is the use of water, and potentially waste streams, as propellant in electric engines. Water, life support and consumables are critical elements in a long duration mission, and in a conventional ship, are dead weight that must be pushed around by propellant that cannot be used for other purposes. Water in a spacecoach, on the other hand, can be used for many things before it is reclaimed and sent to the engines, and it can be treated as working mass. This, combined with the increased propellant efficiency of electric engines, leads to a virtuous cycle that results in dramatic cost reductions compared to conventional ships while increasing mission capabilities. Cost reductions of one or two orders of magnitude, which would make travel to destinations throughout the inner solar system routine, are possible with this approach.

Water is, for example, an excellent radiation shielding material, comparable to lead on a per kilogram basis, except you can’t drink lead. It is an excellent thermal battery, and can simply be circulated in reservoirs wrapped around the ship to balance hot and cold zones (this same reservoir doubles as the radiation shield). When frozen into fibrous material to form pykrete, it forms a material as tough as concrete, which can potentially be used for debris shielding or for momentum wheels, and if positioned correctly, can double as a supplemental radiation shield. If mixed with dilute hydrogen peroxide, which is safely stored at low concentrations, oxygen can be generated by passing it through a catalyst, similar to a contact lens cleaner. Dilute H2O2 is also a potent disinfectant, and can also be used to process human waste, as is done in terrestrial wastewater treatment plants. Anything the crew eats or drinks can be counted as propellant, as the water can be reclaimed and used for propulsion. This greatly simplifies planning for long missions because the longer the mission is, the more propellant you have in the form of consumables. This will also provide excellent safety margins and enable crews to survive an Apollo 13 scenario in deep space.

A spaceship that is mostly water will be more like a cell than a conventional rocket plus capsule architecture. Space agriculture, or even aquaculture, becomes practical when water is abundant. Creature comforts that would be unthinkable in a conventional ship (hot baths anyone?) will be feasible in a spacecoach. Meanwhile, inflatable structures will eventually enable the construction of large, complex habitats that will be more like miniature O’Neill colonies than a conventional spaceship [4].

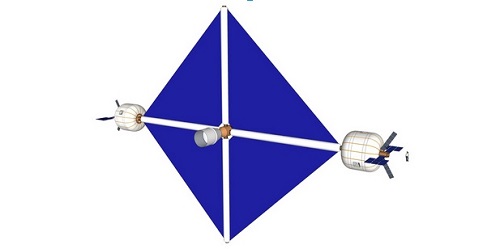

In the book, Alex and I present a reference design that combines inflatable structures and thin film PV arrays to form a kite-like structure that both has a large PV array area, and can be rotated to provide artificial gravity in the outer areas [5]. The ability to generate artificial gravity while providing ample radiation protection solves two of the thorniest problems in long duration spaceflight. Alex wrote an excellent fictional treatment of the concept for Centauri Dreams called Spaceward Ho! This is intended as a straw man design to kickstart design competitions. We envision a series of design competitions for water compatible electric propulsion technologies, large scale solar arrays, and overall ship designs. Much of the reference design can be validated in ground based competitions and experiments, followed by uncrewed test vehicles (similar to what Bigelow Aerospace did by flying its Genesis I and II habitats in low earth orbit).

Spacecoaches are possible not because of any one insight or breakthrough, but because of the convergence of improvements in component technologies, specifically thin film photovoltaics, electric propulsion, and inflatable structures. The combination of the three, particularly when you add water for propulsion, leads to one or two order of magnitude improvements in mission economics.

Thin film solar photovoltaics, which enable the construction of large area PV sails, will enable ships to generate hundreds of kilowatts to several megawatts of electrical power (thin film PV material coincidentally is much more resistant to radiation than conventional silicon PV material) [6]. While thin film solar is not as efficient as silicon in terms of power per unit area, from a power density (watts/kilogram) standpoint, it offers multiple order of magnitude improvements, and will continue to improve for decades due to dematerialization in manufacturing processes.

SEP (solar electric propulsion) is a well understood, flight ready technology. Engines that function with water or gasified waste will be well suited to the spacecoach architecture. We simply need to test existing SEP technologies with water and waste streams to pin down performance and efficiency numbers, which can be done via an X-Prize style engineering competition. Scaling them to propel a large (40 tonne) ship will be done by clustering them in arrays, so there will be no need to build a single high power engine when an array of many 10-20 kilowatt units will do just fine, while also adding redundancy. One interesting discovery we made while doing our analysis is that ultra high specific impulse engines, such as VASIMR, are neither necessary nor desirable. Engines that operate at the low end of the electric propulsion envelope still yield excellent economics due to the synergies created by using water as propellant, while also being able to operate with less electrical power per unit of thrust, which reduces PV array size and mass.

Inflatable/expandable structures are just now beginning to be recognized as a flight ready technology, with Bigelow Aerospace’s BEAM unit due to fly on the ISS later this year. Bigelow already has two uncrewed inflatable habitats in low earth orbit. The basic idea with inflatable structures is to replace a rigid metal hull with a flexible high strength Kevlar type material and utilize pressurization to inflate and deploy the structure. This also enables a large habitable space to be compacted into a standard cargo fairing, thus requiring a minimal number of surface launches for initial delivery to orbit. We expect this technology to improve, both in terms of mass per unit of habitable space (currently about 60 kg per m3), and in terms of the types of shapes that can be created. [7]

Spacecoaches will not be mission specific ships. Even the first generation ships will be able to travel to many destinations within the inner solar system. They will be fully reusable, travelling from a high earth orbit or a Lagrange point to and from their destinations, without ever entering a planetary atmosphere. Spacecoaches will be able to travel to cislunar space, Mars, Venus, NEOs and maybe even Ceres and the Asteroid Belt. They can also be dispatched for asteroid interception and deflection missions on short notice. This is a huge departure from conventional spacecraft which are purpose built for a specific mission, usually Mars, that is planned decades in advance. Mars is certainly an interesting destination, but Ceres, with its abundant water resources and shallow gravity well, may turn out to be an even more interesting destination for human exploration and settlement.

The amount of water required for propellant on any given route will vary depending on the delta-v needed, and also the specific impulse of the engines on board, but water is easy to handle and store. Need to add an extra two kilometers per second to your delta-v budget? Just add water! (or replace the electric engines with slightly more efficient models). Because water is so easy to handle compared to conventional propellants, this will also simplify the construction and operation of orbiting fuel depots, which will be little more than orbiting water tanks.

Simplicity and upgradability is another key design element of the spacecoach. We assume that component technologies will continue to improve for decades. So instead of designing spacecoaches to fly only with today’s technology, they will be designed more like personal computers were in the 1980s. The original PCs were built around a common electrical and communication bus, the ISA bus, which allowed memory, CPUs and peripherals from many manufacturers to be combined. If you wanted to, you could buy the component parts from catalogs and build your own PC from scratch.

We envision something similar for the spacecoach, for the electrical system and engines in particular, which will have standard electrical and fluid interconnects, and uniform form factor requirements. The engines will also be mounted in a sealable compartment that can be pressurized so the crew can replace or upgrade engines without doing an EVA. This will not only make spacecoaches field upgradable, but will also reduce the need to design engines for extreme reliability. If a few units fail, crews would replace them in an operation not much different than replacing a rack mounted server. Upgrading engines will be the best way to improve performance and reduce costs, as a small increase in specific impulse can yield significant mass and cost reductions, especially for high delta-v routes like Ceres and the Asteroid Belt.

And what about cost?

Mention crewed missions to Mars, much less anywhere else, and people automatically assume you’re talking tens of billions of dollars as a starting point. We modeled approximate round-trip mission costs to destinations throughout the inner solar system, using a 40,000 kilogram (40 tonne) dry hull and SpaceX’s published launch costs to get materials, including water, into low earth orbit ($1,700/kg via Falcon 9 Heavy [8]), with electric propulsion (Isp between 1,500 to 3,000s) from there (electrode-less Lorentz force thrusters using water operate in this range). Among the missions we modeled were EML-2 (Earth Moon Lagrange point 2) to/from cislunar space, Martian moons, NEO interception, Venus orbit and Ceres. Even with engines operating at the low end of the electric propulsion performance envelope, our models predicted per mission costs in the hundreds of millions of dollars, a one or two order of magnitude reduction compared to conventional missions, some of which, such as a crewed mission to Ceres, simply are not possible via chemical propulsion.

Such large cost reductions are possible due to a combination of the fuel efficiency of electric engines, and the synergies created by using water as propellant. On one hand electric engines require far less propellant for a given delta-v. On the other, virtually everything the crew consumes or uses for life support can eventually be sent to the engines. As a result the only dead weight on the ship is the hull and whatever non-consumable materials and equipment are brought on board, which will also allow spacecoaches to carry larger crews. Reusability will also enable operators to amortize development and construction costs across many missions.

Spacecoaches are also well suited for in situ resource utilization. Should we reach low gravity destinations with accessible water (Ceres is an especially interesting location), it will eventually be possible to refuel spacecoaches at these destinations, or even ship water inbound to cislunar depots. We assume for now that spacecoaches are fully supplied from Earth, but exploring ISRU destinations and capabilities will be a high priority early on. Partially reusable launch vehicles offer another way to reduce costs. Water will be an ideal payload for a heavily re-used Falcon 9R booster. Unlike most payloads, it has essentially zero replacement cost, so the launch operator can fly the reusable boosters until they fail, and can learn about potential failure modes and fixes in the process (all while delivering more water to orbit).

If you are part of a team working on electric propulsion technology, here’s one way you can help make these a reality. Test your engine with water vapor, carbon dioxide and gasified waste (or a good analogue), and publish your results. The most important parameters ship designers will be interested in are specific impulse, efficiency (ideally the “wall plug” efficiency of the entire system so it can be modeled as a black box) and thrust/mass ratio. We already know several SEP technologies work reasonably well with water, but it will be great to examine all systems to see how well each works with water, compare performance across a variety of technologies, and identify opportunities for further improvement.

It is easy to be cynical about new spaceflight concepts, especially one that promises large cost reductions, but most of this can be validated on the ground and via uncrewed testbeds in a short time and at little expense. It is a paradigm shift, and that will take people some time to accept. The rocket + capsule design pattern served us well in the early years of spaceflight, so its hard to get away from that, but it’s time to move on to something that is more adaptable, something that’s more like a ship that can sail wherever her captain wants to go.

Spacecoaches will form the basis for a real world Starfleet, a fleet which will grow as ships are built, and which will reach new destinations as component technologies continue to improve in the coming decades. They will open the inner solar system out to the Asteroid Belt to human exploration and settlement, and with some spacecoaches operating in cislunar space, humanity will also have a rapid response capability should we be surprised by the discovery of an Earth threatening object.

Visit spacecoach.org to learn more, and to subscribe for notices about the upcoming book, which examines the spacecoach reference design and potential missions in detail. If you are interested in obtaining an advance copy of the book, acting as a technical reviewer or inviting us to speak, please get in touch.

References

[1] “Reference Design for a Simple, Durable and Refuelable Interplanetary Spacecraft”, B. S. McConnell; A. M. Tolley (2010), JBIS, 63, 108-119

[2] Image credit: Frank Tinsley/American Bosch Arma Corporation, 1954

[3] “Possibilities of Electrical Space Ship Propulsion,” E. Stuhlinger, Bericht über den V Internationalen Astronautischen Kongreß, Frederich Hecht, editor, 1955, pp. 100-119; paper presented at the Fifth International Astronautical Congress in Innsbruck, Austria, 5-7 August 1954

[4] “A Shape Grammar for Space Architecture – I. Pressurized Membranes”, Val Stavrev* Aeromedia, Sofia, Bulgaria, 40th International Conference on Environmental Systems, http://www.spacearchitect.org/pubs/AIAA-2010-6071.pdf

[5] Image credit: Rüdiger Klaehn

[6] “Super radiation tolerance of CIGS solar cells demonstrated in space by MDS-1 satellite”, Photovoltaic Energy Conversion, 2003. Proceedings of 3rd World Conference on, 18-18 May 2003, pp. 693 – 696 Vol.1

[7] Estimate based on BA330 mass per cubic meter of habitable space, per Bigelow Aerospace’s published specifications

[8] Per SpaceX published launch cost and delivery capacity for Falcon 9 Heavy, as of April 2015

@Swage, we’ll be making the parametric model available at spacecoach.org

It’s written in Python and we’ll make the source code available as well. Look for that in the next week or so. (Just follow spacecoach.org and you’ll get a notification when it’s available).

The parametric model we use to estimate the cost of spacecoach missions is now available at http://www.spacecoach.org (source code is also available via our github repo). The model forecasts approximate mission costs as a function of factors including:

* engine specific impulse (across a range of values from 1,000-5,000 s)

* the cost of ground based ship design and construction

* the cost to launch equipment to LEO (assume $1,700/kg via F9H)

* the cost to launch water LEO ($1,700/kg via F9H, with options to reduce costs if F9R becomes viable)

* the cost to boost water and material from LEO to EML-2 via electric propulsion

* the cost to launch the crew and CRV direct to EML-2 via chemical propulsion (F9H used as proxy for this)

* number of missions per ship lifetime

Basically what it shows is that per mission costs, even for ambitious destinations like Ceres, will be feasible at a cost in the hundreds of millions of dollars, 1/10th to 1/100th the cost of a conventional mission architecture.

I am addressing to whoever got the respective data, i guess :)

Background is that i’d like to break it down for a Mars mission, a task that most likely surpasses my abilities by a wide margin, nevertheless i read a bit into rocket equations lately, so that peeked my interest. I also listened to a speech of Dr. Zubrin and his Mars direct approach with unfueled return vehicles which synthesize fuel on Mars. I hoped to combine those two approaches. Not to mention that NASA just issued a public challenge for a sustainable Mars transport system. I guess here are a lot of people who can do better or foremost get it done at all, so there you go.

Thanks for the reply, it is appreciated.

Perhaps it would make sense to redirect an ice body for orbital refueling also, hmm…