Talking about issues of long-term maintenance and repair, as we have been for the past two days, raises the question of what we mean by ‘self-healing.’ As some commenters have noted, the recent Caltech work on computer chips that can recover from damage isn’t really healing at all. Caltech’s researchers zap the chip with a laser, but there is no frantic nanobot repair activity that follows. What happens instead is that sensors on the chip detect the drop in performance and go to work to route around the damage so the system as a whole can keep performing.

So the analogy with biological systems is far-fetched, and we might think instead of Internet traffic routing around localized disruptions. It’s still tremendously useful because CMOS (complementary metal-oxide-semiconductor) chips can start acting flaky depending on factors like temperature and power variations. Problems deep inside a chip generally force us to replace an entire piece of equipment — think cell phones — whereas a chip that can smooth out disruptions and continue to perform more or less as before would add to product life.

Restoring Function Inside the Chip

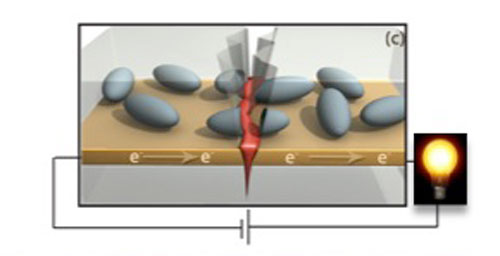

While the Caltech work proceeds, researchers at the University of Illinois at Urbana-Champaign have taken a different approach to electronic chips. They put tiny microcapsules filled with eutectic gallium-indium — chosen because it is highly conductive — into experimental circuits so that when the circuits were broken (the voltage falling to zero) the ruptured microcapsules ‘healed’ them within a millisecond. The voltage measured prior to the break was quickly restored. The team worked with microcapsules of different sizes to measure their effects, learning that a mixture of 0.01 mm and 0.2 mm capsules produced the best result.

The implications of this kind of work for future space missions were not lost on aerospace engineering professor Scott White, who told the BBC:

“The only avenue one has right now is to simply remove that circuitry when it fails and replace it — there is no way to manually go in and fix something like this… I think the real application area that you’ll see for something like this is in electronics which are incredibly difficult to repair or replace — think about satellites or interplanetary travel where it’s physically impossible to swap out something.”

Image: Self-healing electronics. Microcapsules full of liquid metal sit atop a gold circuit. When the circuit is broken, the microcapsules rupture, filling in the crack and restoring the circuit. Credit: UIUC/Scott White.

All of this comes out of work into extending the lifetime of rechargeable batteries (see Self-healing electronic chip tests may aid space travel for more). White said that physically building new circuits every time we need new functionality may give way to circuits that last longer, circuits whose redesign is keyed more to software upgrades than constant hardware changes. Imagine cell phones rendered more sustainable by the presence of ‘self-healing’ circuitry that can repair tiny cracks that would otherwise cause the device to stop working.

Healing Spacecraft Composites

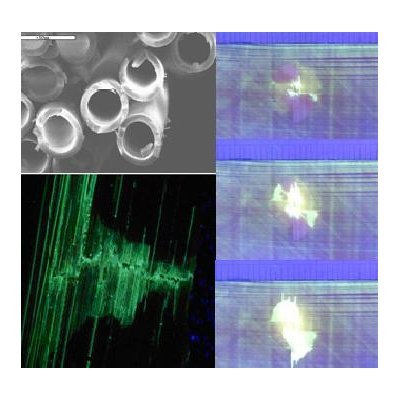

We’ll see how the electronics industry reacts to these ideas when the technology becomes generally available. Meanwhile, the implications for deep space and other environments where chips are hard to replace are clear. This in turn reminds me of a study funded by the European Space Agency back in 2006. Carried out at the University of Bristol, it involved materials that could be used on the superstructure of space vehicles. Cracks caused by temperature extremes or the impact of dust grains traveling at several kilometers per second can build up over the lifetime of a mission, weakening the structure and threatening catastrophic failure.

The Bristol team, led by Christopher Semprimoschnig (ESTEC) inserted hollow fibers filled with adhesive materials into a resinous composite similar to that used in spacecraft components. The glass fibers were designed to break when any damage to the spacecraft ‘skin’ occurred, releasing the liquids needed to fill the cracks. Semprimoschnig likened the process to what happens when humans cut themselves and their blood hardens to form a protective seal that allows new skin to form underneath. This ESA news release provides more background.

Image: Hollow fibers just 30 micrometres in diameter thread the new material. When damage occurs, the fibers break releasing liquids that seep into the cracks and harden, repairing the damage. Credit: ESA.

My assumption is that advances in both biology and nanotechnology are going to provide startling breakthroughs in materials that will make autonomous repair — whether we call it true ‘healing’ or not — possible in settings where no human intervention is possible. The worldships we talked about last week would be repaired and maintained by their inhabitants, but robotic probes on century-long journeys will need every tool in our arsenal to keep themselves functional. A truly autonomous spacecraft really does mimic biological systems in its ability to repair and adapt. Learning how to build it is a priority for future starship design.

I am sorry, it could just be my own mind, but those “Microcapsules full of liquid metal” look so conspicuously like the famous blue pill, the savior of the middle-aged man.

;-)

I’m struck (no pun intended) to finally realize the value of a biologically-based skin for these deep space probes. An outer layer that freezes solid, inner layers that have liquid properties maintained via internal waste heat from the probe that, when exposed to the cold vacuum by a break in the frozen surface, itself freezes to staunch the leak, while circulatory processes restore and replenish the wound, eventually growing repaired layers to restore the outer mold line of the frozen surface. A liquid-based skin would also provide some shielding, depending on its depth, against radiation damage for inner layers, and the damage to the skin from radiation effects would itself be cleansed through the circulatory system and some kidney-like mechanism.

Wouldn’t it be interesting if Icarus winds up being more like Moira (to name one Science Fiction bio-based transport) than Voyager.

Sorry, the ships name was Moya (thinking Farscape, here)

Seeing is believing…you’re closer to a working starship than you realize….

in fifty more years, you’ll not even be ninety then…..didn’t someone once say the devil is in working out all the little details….

Not only would the mechanical workings have to imitate biological systems, but also these would have to be radiation hardened, especially if appreciable amounts of c is abtained.

Wasn’t HAL 9000 made at the University of Illinois at Urbana according to 2001? And now they are making self repairing electronics, so that HAL will be unstoppable! ;)

@dad2059. That is a good point, but I think biology helps here. The radiation will mostly impact the front of the vehicle, as will particle impacts. The usual approach is to use a massive shield to protect the ship – e.g. the ice shield as depicted for the Magellan starship in Clarke’s “The Songs of Distant Earth”. However, instead of letting the shield erode to become thin, biology would allow constant replacement of the shield from below, maintaining the thickness. The best analogy I have is the growth of mollusc shells which occurs in the mantle below the external shell. I have little doubt that this approach could be made to work quite easily, either with real biology, a mechanical analog or even chemistry (e.g. electro-deposition of minerals as done for “sea crete”).

The same sorts of approaches would work for spacecraft hulls. Even today would could probably manufacture hulls that are ice on the outside, and liquid inside, to absorb meteoroid impacts and “heal”. The beauty of biology is that more efficient nano scale composites have been evolved – mollusc shells have extremely good mechanical properties – that would reduce the mass and improve the properties of the hull and shield. (Is there any data on radiation or particle impacts on the mechanical property changes of biological structures like shells vs. standard materials like metals, plastics and ceramics?)

I don’t expect star ships (even interplanetary ships) to completely mimic biology (engines?), but I wonder if cyborgs are the way to go.

Liquid metal electronics? Never mind self-repairing circuits, we’ve found the ship’s crew.

I just pity the poor extra-solar planet where a starship from Earth manned by T-1000s rocks up…

One important consideration when talking about hull materials is the strength to weight ratio. Aluminum, steel, and carbon fibers have any existing biological materials beat by many lengths, here. Think of a wooden spaceship. It just does not sound right.

Now if we had biological carbon fibers, then we’d be talking.

Electronic failure is a predicted scenario for deep spacecraft. Getting away from hardening to self-repair is an interesting alternative. I guess this is the intermediate step for Von Neuman repicators? Sprinkling a system of assemblers on a comet or asteroid and you ‘grow’ a spacecraft? I wonder how long this process will take?

To repeat what I posted in the article on self-healing circuits:

Why not skip trying to reinvent the wheel with mechanical devices and go with a system that has been perfecting itself for over 4 billion years on this planet by making a bioship.

http://en.wikipedia.org/wiki/Bioship

The first 15 minutes of the movie Life Force is one of my favorite sci-fi movie sequences (the rest of the movie was more of a horror flick).

The alien spaceship is immense and ancient. If we build a starship with a shell a couple dozen feet thick like that then we have plenty of material to recycle as parts and no radiation to worry about.

We just have to get out of this box we are in concerning size; a Starship will be tremendous.

And yet wooden aircraft like the WWII Mosquito made of plywood were incredibly resistant to damage.

Not quite pure biology, but nano crystalline cellulose (made from wood) is extremely strong.

Spider silks are also high strength to weight materials.

Biology has evolved very strong structures that are composites, offering high strength and fracture resistance.

So either we find ways to make synthetic biology produce these sorts of material structures directly, or the ship is part living, part machine and there are small scale industrial processes to convert the biology to superior materials.

We don’t necessarily need the strongest structures, but rather those that can best survive the journey. Weaker, self repairing ones may be better than stronger, fixed ones.

“We don’t necessarily need the strongest structures, but rather those that can best survive the journey.”

I would guess composites are more vulnerable to radiation than monolithic material but that is just a guess.