Before we can go to the stars we’ll need to build a robust infrastructure in our own Solar System. While most attention seems to be devoted to propulsion issues, I’m convinced that an equally critical question is how we can create and sustain closed-loop life support systems for such missions. Our point man on this is Ioannis Kokkinidis, who brings a rich background from his Master of Science in Agricultural Engineering (Agricultural University of Athens) and Mastère Spécialisé Systèmes d’informations localisées pour l’aménagement des territoires from AgroParisTech and AgroMontpellier, along with a PhD in Geospatial and Environmental Analysis from Virginia Tech. Here Dr. Kokkinidis discusses what has been done so far in the matter of growing foods in space, and takes us back to a mission that might have been, a manned flyby of Venus. As Ioannis notes, getting space foods up to the sumptuous standards of Greek cuisine will indeed be a challenge, but we’re at least making progress.

by Ioannis Kokkinidis

Introduction

A few years ago the Greek press was buzzing with a story about the European Space Agency asking two French caterers to create a meal for Mars based on nine foods: rice, onion, tomato, soybeans, potatoes, lettuce, spinach, wheat and spirulina. The news story was the first time I was exposed to the ESA’s MELiSSA project, which aims to produce food through an artificial ecology for solar system colonization, including space stations and spaceships. A somewhat related American project to grow food in microgravity is the VEGGIE project, which has recently made headlines by growing several plants which were consumed by astronauts on the International Space Station. The subject of this post is to describe two leading edge projects to produce food in a space environment. I am not and have never been affiliated with either of the projects, I have never met any of the people associated with either project nor is anyone asking me to publicize these projects. I am simply a learned amateur, albeit one with graduate degrees in agronomy who is fascinated by the projects and their potential.

MELiSSA

The Micro-Ecological Life Support System Alternative (MELiSSA) initiative is a European Space Agency project with almost 30 years of history behind it. Its origin lies in the flight of two tubes of nostoc algae in a recirculating system to space on the Chinese FSW-0 No 9 recoverable mission in 1987. In 1989 the MELiSSA Foundation was formed to create a closed loop artificial ecosystem for long spaceflights, based on aquatic ecosystems. MELiSSA aims to replace the current generation of mechanical Environment Control and Life Support Systems (ECLSS) with a new one based on biology, which will not only remove metabolic waste from the various streams (air, water) but also produce food in the process. The tool to accomplish this task is the MELiSSA cycle.

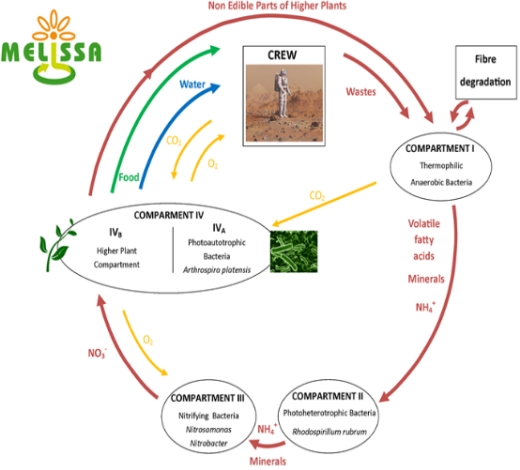

Fig 1: The MELiSSA cycle © ESA from http://www.melissafoundation.org/. The cycle has five compartments.

Compartment I: The liquefying compartment

This compartment gathers all the organic waste created in the spaceship and aims to convert it into ammonium, CO2, volatile fatty acids and minerals. For biosafety and efficiency reasons this compartment operates in thermophilic conditions (i.e. 55 C). The main biological functions involved are proteolysis, saccharolysis and cellulolysis. While saccharolysis is trivial, after all sugars are a main biological source of energy for most species, proteolysis and cellulolysis have proven more difficult to optimize, with proteolysis having an efficiency of 70% and cellulolysis of 44% in the cycle. Considering that despite billions in public and private investment in Europe and the United States to increase cellulolysis efficiency, cellulosic ethanol has not entered the market in meaningful quantities, these efficiency figures are pretty decent for the current state of technology.

Compartment II: The photoheterotrophic compartment

In this compartment volatile fatty acids, ammonium and minerals from component I are further broken down by Rhodospirillum rubrum bacteria into minerals and ammonium. The bacterium has proven very efficient in the process. For more, see this brief video.

Compartment III: The nitrifying component

This compartment has as feedstock urine from the crew, ammonium from compartment II and oxygen from compartment IV. It uses a mix of Nitrosomonas and Nitrobacter bacteria to oxidize ammonium into nitrates, which plants prefer as their nitrogen source

Compartment IV: The photoautotrophic compartment

This compartment is intended is to grow actual food and produce oxygen for the crew. It is divided into two parts: the algae compartment and the higher plant compartment.

- IVa: The algae compartment

In the current iteration of MELiSSA, the cyanobacterium Arthrospira platensis has been selected as the organism grown. This is one of two species (the other being Arthrospira maxima) that are known colloquially as spirulina. Several photobioreactors with this bacterium have been built and a predictive model has been created and validated experimentally.

- IVb: The higher plant component

This component is intended to provide both food and water for the crew. While several crops have been evaluated in the course of the project, 8 have been selected: wheat, tomato, potato, soybean, rice, spinach, onion and lettuce. Currently the status of this component is far less mature than the algae component, they are still compiling the biomass production rates, nutrient and mineral compositions of the plants based both on outside work and their own research.

Component V: The crew component

This is simply the crew component of the spaceship, composed of the astronauts and cosmonauts who consume the food, produce CO2, urine and other waste which is sent to the components of the cycle.

Status

Like all ESA programs, the intention of MELiSSA is not only to provide technology for space exploration but also for applications on earth. It has helped explored the concept of closed loop ecosystems, which are critical to colonize other bodies but also to help understand how earth ecosystems work. A pilot plant that uses rats as the trial crew (component V) has been running since 2009 at the School of Engineering of the Autonomous University of Barcelona. The greywater treatment plant of the Concordia station in Antarctica uses MELiSSA technology while a sensor for CO2 monitoring of sparkling wine has been commercialized. The BIOSTYR© bacterial support for wastewater treatment, commercialized by Veolia, has been derived from MELiSSA compartment III research. Andreas Mogensen conducted two MELiSSA related experiments during Expedition 44 to the ISS, consuming spirulina infused snack bars created by MELiSSA which he also shared with his fellow astronauts in the DEMES experiment, and keeping an eye on some micro-organisms and how they recycle our waste in space in the Bistro experiment.

The most recent news item associated with MELiSSA was the opening of a new facility called AlgoSolis to cultivate algae at an industrial scale in Saint-Nazaire in France. It seems that it is the intention of the project to construct a MELiSSA loop in the ISS or a future space station, though the concept still requires technological maturation. This is a very interesting project to follow in the future.

VEGGIE

The Vegetable Production System (VEGGIE) experiment is an experiment of NASA’s Human Exploration and Operations Mission Directorate to grow salad crops in the International Space Station run by the Kennedy Space Center and Orbital Technologies Corporation (ORBITEC) of Madison WI, a subsidiary of Sierra Nevada Corporation. It is not the first plant growth experiment in space, the Bulgarian/Russian SVET SG (Space Greenhouse) experiment grew various plants on a series of experiments aboard the Mir space station in the 1990’s, several of those in partnership with NASA. These however were biological experiments intended to study plant growth in microgravity; cosmonauts were not supposed to consume the plants though some have admitted to nipping bits. The Veggie experiment intends to grow fresh food for astronaut consumption on the ISS. So far the experiment has had three phases, named Veg-01, Veg-02 and Veg-03 and has been conducted during Expeditions 35/36, 39/40, 41/42, 43/44, 45/46, 47/48 and 49/50.

Overview

VEGGIE builds on heritage from the SVET SG experiment on Mir, the Biological Production System of Expedition 4 and the failed efforts of Expedition 2 astronaut Jim Voss and Expedition 6 astronaut Don Pettit to grow plants on old food bags (see http://www.orbitec.com/documents/Veggie-APH.pdf). It is made of a plant growth chamber which is made of modular planting pillows, an LED bank for lighting and a fan for humidity control. It weighs 7.2 kg and has external dimensions 53 by 40 cm (=0.212 m2) with a root mat of 0.16 m2 and a growth height of 45 cm. It provides lighting and nutrients, having a 2 l fluid reservoir, but depends on the ISS ECLSS for temperature and CO2. It draws 115 Watts of peak power, is able to support different day/night lengths for experiments and contains a data logger that records temperature, humidity and pCO2 (see http://spaceflight101.com/iss/veggie/). The plants grow on the planting pillows, containing the substrate, fertilizer and seeds, which are of single use and arrive in ready-to-activate form from earth. It is deployed in an EXpedite the PRocessing of Experiments to Space Station (EXPRESS) Rack.

Veggie hardware validation test (Veg-01)

Veg-01 had a variety of goals including a shakedown of the system to see if the experimental apparatus works in space. VEGGIE was delivered to the ISS by the SpaceX CRS-3 mission launched on April 18 2014. Expedition 39 flight engineers Steve Swanson and Rick Mastracchio installed it at the European Columbus module on May 7 2014 and activated it the next day. They used 6 planting pillows of ‘Outredgeous’ red romaine lettuce, having a substrate of two different sizes of arcillite (3 of one and 3 of the other), a calcined clay media used on baseball fields that included fertilizer. Two sizes were used so as to compare root zones between the two media, so as to determine water and root distribution for future investigations.

The pillows then received about 100 milliliters of water each to initiate plant growth. 24 hours after activation on the ISS an identical VEGGIE experiment was activated on the ground at KSC to serve as control (see also http://spaceflight101.com/iss/veggie/). Steve Swanson, who by that time had become the commander of Expedition 40, harvested VEGGIE on June 10, 33 days after planting. The next day the control experiment was harvested on the ground. Two plants on the ISS experiment were lost due to drought stress. The tops of the surviving lettuce were cut away from the plant pillows and swabbed for microbial samples. The pillows and bellows also were swabbed.

The plants, sample swabs and a couple of the plant pillows were packaged and placed in the ISS’ minus-eighty-degree freezer for storage. The crop, along with the pillows and sample swabs were returned from the ISS on the SpaceX CRS-4 mission which splashed down on October 25 2014. The lettuce was analyzed for microbes on the ground and found to be within safe limits, for that matter it had a lower microbial count than what is usual for lettuce on the market. A second crop was activated in early July 2015 by Commander Scott Kelly, who had arrived on the ISS on March 28 2015. Thirty three days later they were harvested in turn, having lost only one plant and on August 10 2015 expedition 44 astronauts wiped the lettuce leaves with citric acid-based, food safe sanitizing wipes before consuming them raw. See http://www.nasa.gov/mission_pages/station/research/news/meals_ready_to_eat.

Veg-02

There is conflicting information online whether Veg-02 is just the zinnia experiment (described below), if it also included the second lettuce experiment mentioned in the previous section or for that matter if there even was a Veg-02 experiment, rather than skipping the number and moving directly from Veg-01 to Veg-03. In any case what follows is a detailed description of the zinnia experiments compiled from available online sources.

The planting pillows with the ‘Profusion’ zinnia seeds for the Veg-02 experiment were carried to orbit along with the rest of the VEGGIE apparatus on the SpaceX CRS-3 resupply flight. These plants received quite a bit of attention from Commander Scott Kelly during his Year in Space mission; he took care of the plants and tweeted about them several times. On November 16 2015 astronaut Kjell Lindgren activated the experiment, which was the first flowering plant experiment grown on the ISS, 3 days after activation of the control experiment at KSC. The experiment was composed of a total of four plants and lighting was set on a photoperiod of 10 hours day and 14 hours night in order to stimulate flowering.

The plants started to grow [http://www.nasa.gov/image-feature/first-flower-grown-in-space-stations-veggie-facility] but two weeks into their growth period, NASA astronaut Kjell Lindgren noted that water was seeping out of some of the wicks – the white flaps that contain the seeds and stick out of the tops of the plant pillows. The water partially engulfed three of the plants. Within 10 days, scientists noted guttation on the leaves of some of the plants. Guttation is when internal pressure builds in the plants and forces excess water out of the tips of the leaves. It occurs when a plant is experiencing high humidity.

Additionally, the zinnia leaves had started to bend down and curl drastically. This condition, called epinasty, can indicate flooding in the roots. The anomalies all pointed to inhibited air flow in the plant growth facility that, when coupled with the excess water, could have the potential to cause major problems to the crop. Commander Kelly, who took over the experiment after Lindgren returned on Earth December 10, noted that the plants had grown a mold. On December 22nd, after late night consultations with the ground crew, he cut the two affected plants off and put them in cold storage for return to Earth. Then he increased the fan speed to reduce humidity. Scott Kelly, though, reported on Christmas Eve that the reverse problem was currently happening, the plants were getting too dry. Watering was scheduled for December 27, but despite the advice of the ground crew, he decided to take the initiative and water them on Christmas Eve. He then tweeted one of his most memorable tweets.

Our plants aren't looking too good. Would be a problem on Mars. I'm going to have to channel my inner Mark Watney. pic.twitter.com/m30bwCKA3w

— Scott Kelly (@StationCDRKelly) December 27, 2015

By January 8 the flowers were on the rebound, leading to another tweet.

Some of my space flowers are on the rebound! No longer looking sad! #YearInSpace pic.twitter.com/HJzXaTItIf

— Scott Kelly (@StationCDRKelly) January 8, 2016

while on January 12 they had begun to flower. The zinnia plants on the ground were harvested on February 11 while those in space on February 14, Valentine’s Day. See http://www.nasa.gov/mission_pages/station/research/news/flowers.

Veg-03

The aim of the Veg-03 experiment is to build on the success of the previous VEGGIE experiments by growing ‘Tokyo Bekana’ cabbage along with ‘Outredgeous’ lettuce as food crops. Plants are again to be grown in two different sizes of arcillite substrate with specialized fertilizer. Eighteen planting pillows (12 of cabbage, six of lettuce) were prepared at Kennedy Space Center on early April 2016, by gluing the seeds using guar gum to the Teflon and Kevlar envelopes [https://blogs.nasa.gov/kennedy/2015/06/18/future-lettuce-planting-the-seeds-for-veg-03/]. They were then packed in gas-impermeable bags and then into cargo transport bags so as to be shipped on the ISS with the SpaceX CRS-8 mission to the ISS [https://blogs.nasa.gov/kennedy/2016/04/08/veg-03-plant-pillows-readied-at-kennedy-space-center-for-trip-to-space-station/]. First lady Michelle Obama planted cabbage seeds from the same batch that were shipped to her from KSC at the White House vegetable garden on April 5th 2016. She was assisted in that task by NASA Deputy Administrator Dava Newman, astronaut Cady Coleman, Brad Carpenter, chief scientist for space life and physical sciences at NASA, Gioia Massa, NASA Veg-03 science team lead at Kennedy and kids from Bancroft Elementary School and Harriet Tubman Elementary School [http://www.nasa.gov/feature/nasa-s-veg-03-seeds-planted-in-first-lady-s-white-house-garden]. SpaceX CRS-8 launched on April 8 2016, was captured on April 10 and the experiment is awaiting activation. Future plans for VEGGIE include growing dwarf tomato seeds in 2018.

Overview

Despite its modest size VEGGIE is the largest plant growth chamber ever launched to space. So far over three growth periods it has produced only one lettuce crop that was consumed by the inhabitants of the ISS following a 33 day growth period. Alas I did not find a news item on whether it was actually all consumed in one or several meals. If we wished to scale the experiment to producing a significant fraction of the food consumed by the astronauts and cosmonauts in space, as is the purpose of the MELiSSA experiment, we have the issue that the ISS is simply not big enough, despite being the largest space station in history. The complete length of the ISS modules from one edge to the other is 51 m. Assuming a 4 m average module diameter this would mean an opening area of 200 m2.

Under intensive agriculture we would most likely need on Earth around 250 m2 per inhabitant per year, though this needs to be validated in space conditions. But the ISS is three dimensional; we could say fit throughout the ISS modules enough VEGGIE modules to have sufficient growth area in the volume provided, if there were enough EXPRESS racks. Other issues would still need to be resolved. If a single 0.212 m2 VEGGIE module consumes 115 W of peak power, then 250 m2 of VEGGIE modules should consume 135,6 kW of power. The ISS power system produces, according to Wikipedia, between 84 and 120 kW of power on each orbit. Furthermore 1000+ Veggie modules would require quite a bit of astronaut attention and time that might not be available: Scott Kelly was aware of the rot issue in the zinnia experiment on the single Veggie module he was tending at least two days before he intervened, but he had to delay his intervention due to an unplanned spacewalk. Growing food in space requires very significant amounts of space and human resources, which is why so far space food has been grown, prepared and sent to space from Earth.

Cooking in Space

After growing food in space we would most likely need to cook it. While Veggie is intended to grow only raw food, MELiSSA intends to produce raw materials for balanced, cooked, or at least somewhat prepared, meals. This raises the issue of cooking in space, especially under microgravity conditions, which is still in a rather primitive form. Expedition 18 astronaut Sandra Magnus has produced a slideshow and an article of her cooking efforts in space. I admit that I am showing my cultural bias as a Greek here but with the exception of putting onions and garlic with olive oil at the Russian food warmers for several cycles, the rest of her cooking would not qualify as cooking in my book but rather as recombination of already partially prepared foods. Then again I have to admit that not everyone’s baseline for cooking is their grandmother spending two or three hours preparing lunch in the kitchen followed by a couple of hours of baking in the oven to cook it.

Moving from having raw produce to fully prepared cooked food requires several steps that have yet to be demonstrated in space. Let us assume that we have grown wheat and we wish to create a taco shell, a foodstuff quite popular with ISS astronauts and cosmonauts. We would need to separate and shell the wheat grains from the rest of the plant. Then we would need to mill the grains into flour which is a critical step in more ways than one: we depend on modern mills to separate several pathogens from the seeds and protect us from, say, ergotism. Then we would need to turn the flour into dough in microgravity, which is not very conductive to mixing materials that are in different phases. Next we would shape the dough and put it into an oven for cooking, which most likely would have to look like a toaster oven so as to avoid having the shaped dough wander inside the oven along with the convection currents. Then hopefully we would have a taco to fill with what we desire. As we can see we still need to prove that several of these steps can be achieved under microgravity conditions.

Growing space food in perspective

One of the offshoots of the space race was the Apollo Applications Program (AAP), an effort to use the hardware developed during the Apollo program in other uses. It eventually studied three major applications: the Orbital Workshop, a permanent Lunar Base and a Manned Venus Flyby. A central concept of the AAP was the Wet Workshop: The upper stage of either a Saturn IB or a Saturn V (the S-IVB stage) would be launched to space, fire its engines to reach the appropriate trajectory, then the remaining fuel and oxidizer would be vented and the astronauts would move into the tanks after sealing them behind them using tools launched with them placed at the location where the Lunar Module would be during Apollo lunar missions.

In the end only the Orbital Workshop was launched in the form of Skylab, which was a Dry Workshop: It was launched already preconfigured as a habitat from Earth. Skylab can be seen as a prototype for the Manned Venus Flyby spaceship, which after all has been called “Skylab to Venus”. It is unfortunate that in the 5 decades since, very few spaceship plans can claim to have reached the level of maturity that Manned Venus Flyby reached with the launch of Skylab. Only the Soviet Mars Train, released a few years before the collapse of that country, can also claim to be based on space tested systems, more specifically the Mir Space Station and the Russian segment of the ISS which was based on Mir/Mars Train designs. While some of the NASA Mars plans have talked about the use of Destiny derived modules, so far only the Manned Venus Flyby has had a plausible plan using existing hardware in production at the time of its planning. For a review of Mars plans see http://history.nasa.gov/monograph21.pdf.

Skylab holds to this day the record for food weight and portions packed in a single launch. Skylab, like the first generation Salyut stations, lacked the ability to receive unmanned resupply missions and while some food was carried along with the crews, most of the food consumed aboard was carried to space during the launch of the Space Station. More specifically, Skylab was launched with approximately 2500 lbs of food packages and another approximate 350 lbs were launched along with the astronauts, mostly with Skylab 4. I use imperial units in this section because that was what NASA used at the time in the documentation.

The workshop included 5 freezers each weighing about 60 lbs (without the food inside them), 22 unrefrigerated food assemblies at 90 lbs each and 3 overage containers at 30 lbs each (see http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19760011703.pdf). Adding all these numbers up totals 2850 lbs of food and 2370 lbs for the containers, and a system total of 5220 lbs. Considering that the total weight of Skylab without the Apollo CSM at launch was 150,350 lbs, the mass fraction of the food system was 3.5% of total weight, including the food that was later launched. Food without the support equipment was 1.9% of total Skylab weight. Originally Skylab food was packed for 140 days of operation; in the end the three manned missions lasted 171 days and they kept a 10 day contingency margin of food for the last flight in case weather delayed the return of the last crew. My understanding is that when Skylab 4 landed only the contingency food was left on board the station.

The Manned Venus Flyby spacecraft was to last for 400 days. The planners allotted 1800 lbs for the food for the 3 astronauts, a figure that does not include the weight of its containers. Furthermore, the thrown weight of the whole MVF assembly stack was 106,775 lbs of which 37,710 was for the Environmental Support Module and 34,600 for the S-IVB stage and the Instrument Unit [https://www.devin.com/cruft/19790072165_1979072165.pdf]. This would give a food fraction of 1.7%, as opposed to Skylab’s 1.9%.

Now on Skylab the Orbital Workshop weighed 62,500 lbs, IU 4,600 lbs with a total weight (including the 22,200 lbs Apollo Telescope Mount but not the Apollo CSM carrying the astronauts) of 150,300 lbs. If for 181 days of food supplies Skylab need 2850 lbs of just food, for 400 days of supplies they would need 6300 lbs. While it is true that when MVF was studied we had little idea how much food astronauts and cosmonauts needed in space, the differences in mass between the MVF plans and what was their equivalent weight on Skylab offer a cautionary tale on planning without having built any actual equipment. It is rather difficult to find figures online on how much weighs the food that each ISS astronaut or cosmonaut consumes every year, but my understanding is that since the 1970’s actually food weight consumed is more or less the same but packing material weight has significantly decreased.

My foray into the Apollo/Skylab era is intended to show just how small a fraction of spaceship weight is taken by the food system. I have not performed this sort of analysis with later spaceship plans, assuming they were ever that detailed, but even for a two year trip in space (say to Jupiter) food weight should not be a showstopper. Growing food would still be beneficial for psychological reasons and to supply vitamins in a more pleasant form than pills. For long term interstellar travel, when we surpass a trip length of a decade, which is generally the maximum that canned foods survive, growing food will become critical. The projects mentioned in this post will probably be among the ancestors of the systems and their designed used on these starships.

VEGGIE & other such programs ignore the protein issue. Studies find that feeding basic plant lichen, bryophytes, etc to insects produces a lot of protein–which humans need. Plus they’re tastier when well cooked (fried, baked). Not hard to do.

While I am fan of snails, I am not really a fan of entomophagy. I agree that we do need animal protein, I am aware of biology experiments with insects in microgravity but I am not aware of any experiment to produce insects for human consumption in space. In any case my understanding is that to fry insects we would remove parts such as the antennae and legs, cover them with a flour based batter and fry them. This is something yet to be performed in space.

Spirulina and soybeans are high protein foods. In any case for various reasons, most important of which that vitamin B12 is not available from plant sources, an exclusively vegan diet is not well suited for the long term. The taco shells will be filled with cheese and meat along with the vegetables. Even under optimum conditions though it will take long for the cheese and meat to be locally produced, as opposed to coming from earth

In the case of crickets, you would fry the lot and eat the lot, as the Thais do. They are delicious.

Apart from the yuck factor (played up in the movie “Snowpiercer”), there is the risk of insect escape into the facility. If cockroaches or some sort of flying insect got out into the habitat, it might be hard to eradicate them again. I would go for animals that are more palatable and can be controlled. Thus worms and fish make for a better choice, IMO. They also are energetically close to insects in conversion efficiency.

The other problem with insects is that the chitinous exoskeleton makes up a rather large proportion of their mass, and this is indigestible to humans. Great roughage in the diet, but not that great in terms of digestion. We would also need to know what impact such diets might have on the gut microbiome too.

However the point Greg makes about the protein issue is important. This is why I recommend growing food as a supplement, mainly for morale, rather than trying to replace the full diet. Plant food must be cooked in general, or supplemental to high calorie cooked foods like meat, because the energy delivery of uncooked fresh plant material is low and made worse by the energy expended in chewing. It has been suggested that our brains were able to expand because the jaw muscles could be massively reduced once our ancestors learned to cook food. Extreme foodies who only eat raw plant food look terribly emaciated because it is hard for them to extract enough energy to support their metabolism. There is a reason why plant eating mammals need to graze all day.

Perhaps krill would work as well. They are fairly hardy, live at high population densities, are able to eat plankton directly, and can themselves be eaten by people once peeled, as well as fed to other fish. Has anyone looked at them as a food source?

Not to my knowledge

Oh boy, here goes. I am a 62 year old PhD biochemist with some 24 years in the soy and dairy industries. I just knew I knew nutrition. Until my heart attack at age 49. Two weeks later I had the usual quad bypass yet still I had angina. “[My surgeon] couldn’t get it all ” because some of the plaque was too deep into my heart tissue. So I was just waiting for the “big one”.

On a bucket list trip to Florida (from NZ!) to see the last shuttle launch, delayed by bad weather… while waiting, I saw a life changing movie, Forks over Knives, in which much of what I had learned about nutrition was turned on its ear. As a scientist, I recognised that these recommendations of Dr’s Esselstyn, Campbell and others were based on evidence, not archaeology or faith. And they worked. And I was looking at few other options.

I started eating only whole plant foods and 3 weeks later my angina was gone. I could run up hills that used to defeat me at a few steps. I went from 240 lbs to my present 188 without really trying. The list of ailments that just disappeared is immense, all caused by poor diet.

The reason I’m writing is to say that people can get all the protein needed in their diet by eating ordinary plant foods. Correcting for water, there is as much protein in broccoli as there is in steak. A potato is 9% protein…that’s just right. The obsession with “complete protein” is based on myth. In fact, the high sulfur load in animal protein promotes cancer. There is no cholesterol in plants. Little saturated fat. Lots of fiber and phytonutrients.

I know this message is not likely to be believed by many, but I do hope it spurs you to look a little deeper. In space it will be necessary, quoting Hippocrates “to let food be thy medicine”. I contend that there is no place for animal products in long duration expeditions.

We’ve ignored the truth about diet since the 40’s and 50’s. Pioneers like Kempner, Ornish, Pritikin and a continuum of outstanding researchers have pieced the data together. It is now iron clad fact ignored at our peril.

I am happy to provide ref’s and further discussion to interested parties.

It’s a pity that “Forks over Knives” is no longer available to watch for free on Youtube. It is a good documentary,

I do think we need to be a bit careful claiming that plant foods are sufficient. I wouldn’t want to rely on just plants for nutrition during development, and they certainly are not as nutrient dense as meat for proteins and fats. Luckily we are omnivores and can switch food sources fairly easily, depending on availability and needs.

It’s good to hear that changing your diet improved your health.

I’ve been thinking about your comment for some days. I absolutely agree that we humans can extract nutrition from a wide range of foods. So if you are lost in the bush and you can find or kill a beast then by all means eat your fill. But here’s the rub, here at CD we are looking at travel to AC.

We have two choices…wait for physics to transcend the c limit or work within the bounds of the law. We’ve opted for the latter. One logical directive of that decision is to use science to continue to determine the optimal diet for human health and longevity. Coincident with that line of investigation should be the technological development of systems to provide that nutrition to the plucky pioneers.

I do not like sounding so pedantic, and yet my own experience and research clearly indicates the necessity of speaking plainly. There is no room for political correctness or opinion or any of the myriad untruths foisted upon the teeming masses that lead them to make disasterous choices. The “west” is rife with diet-caused disease. Clearly the same principles of good nutrtion apply with respect to “flying Mother Nature’s silver seed to a new home in [a star]”

I’m an interested party and am keen to see those refs you mentioned; my wife and I have been improving our (already good) family diet this last year so that would help a lot, thanks.

(As its off-topic I’m at “squirreltape at gmail dot com”) ;)

Message sent

‘ -Watney

Astronauts are fit, unfit astronauts simply do not make the cut. They have no need to lose weight, rather we need to ensure that they do not. Meat is not necessary for protein but rather for vitamin B12 and for other nutrients that come in different ratios than in plant based food. There is an excessive amount of animal food in the typical American diet, but this does not mean that we have to go the other way and completely eliminate it. In any case what is the optimum diet for people is still subject to debate

No you miss my point. Obesity is not the issue here, agreed. I told my story only to illustrate the point that I like so many others, who were on the very brink of death have restored our health to full vigour by the simple act of eating a diet based on whole plant foods.

Based on these anecdotal episodes, the good scientific evidence of the past 70 years and modern biochemistry the fact is established that the best diet for humans is herbivory consisting of minimally processed plant foods. This is one case where “moderation” is as deadly as cutting down on tobacco.

I argue, therefore, that is the Rx diet for our brave astronauts. Don’t they deserve the best diet science can provide?

The best diet for humans depends on the environment. The Inuit of Greenland require their high fat high calorie fish and seal based diet because they consume copious amounts of energy heating themselves. This is not true for us Mediterraneans, at low altitudes it doesn’t get very cold very often. I reserve judgement as to what is the optimum diet for astronauts for specialist nutritionists and also recognize that a weightless astronaut doing two hours of exercise per day and floating around the rest and a planet based astronaut walking several kilometers and lifting equipment have different requirements. One thing though that I do remember from zootechny class is that plants cannot produce vitamin B12, we can only get from animals and some fungi.

You are wrong about the Inuit. Because they burn a lot of calories does not mean they should eat a high fat diet. Please have a look at these:

J G Fodor, E Helis, N Yazdekhasti, B Vohnout. “Fishing” for the origins of the “Eskimos and heart disease” story: facts or wishful thinking? Can J Cardiol. 2014 Aug;30(8):864-8. http://www.ncbi.nlm.nih.gov/pubmed/25064579

P Bjerregaard, T K Young, R A Hegele. Low incidence of cardiovascular disease among the Inuit–what is the evidence? Atherosclerosis. 2003 Feb;166(2):351-7.

M R Zimmerman. The paleopathology of the cardiovascular system. Tex Heart Inst J. 1993;20(4):252-7.

J Dyerberg, H O Bang, N Hjorne. Fatty acid composition of the plasma lipids in Greenland Eskimos. Am J Clin Nutr. 1975 Sep;28(9):958-66.

I M Rabinowitch. Clinical and Other Observations on Canadian Eskimos in the Eastern Arctic. Can Med Assoc J. 1936 May;34(5):487-501.

Also, you are way wrong about B12. Animals get their B12 from the microbes that inhabit the plants that they eat. So any space-faring mammal will need to supplement with B12. The tiny amounts needed (say 1 mg per week) are easily supplied with a supplement.

I don’t mean to criticise you in a malicious way, but the facts are clearly being miss by you and many (most?) nutritionists. The published literature is rife with the true picture of what constitutes good nutrition. Readers must learn to look at who funds the paper. If it was funded by the Texas Cattlemen’s Association, then you might want to consider that in your critical thinking.

It doesn’t matter what anyone’s opinions are. This is reality, man. We’ve got to get this right from the git go. I like your article and that we are having this discussion. I hope you will consider my points and continue to look deeper.

Since Salyut 2 (alas the cosmonauts of Salyut 1 died on reentry) nutrition in space has been the subject of countless experiments. The link I have on the article on Skylab food also mentions the nutrition experiments there. I am pretty sure that a search both in NASA’s internal academic search engines and on Google scholar will lead to a large series of articles on what is the optimum diet. I do not proclaim to be an expert, my studies were on the intersection of advanced growing systems such as hydroponics, irrigation and large scale changes in the landscape as revealed through GIS manipulation of remotely sensed data. I live nutrition to more expert colleagues. What I do remember though is that vitamin B12 comes from symbiotic bacteria that live in the animal, not from plants. Vegans need to take pills or fortified food for vitamin B12. We did ask our horticulture professors if plants produced B12, their answer was that there was a negligent amount on fruits and vegetables which is believed to come from fungi growing on the surface but will in no way meet the nutritional requirements of people. This is one reason I make sure that I eat shrimp when I am fasting. I prefer nutrition studies that have been funded by the European Commission

Know you to tell if someone is vegan?

Simple. They’ll tell you :-)

Like the aversion to eating insects (or entomophagy– thanks for the laugh!)– our current aversion to a meatless diet will be a thing of the past. And don’t mistake it for anything other than preference. I’m happy to say I’ve been vegan for nearly 30 years. Those who haven’t chosen this life path are surprised when they actually learn about the variety and flavors available. Broccoli every day it ain’t.

Michael

Certainly, I do agree with you about the hearty meals a vegan diet can offer. I try to make the distinction between “whole plant foods” from vegan because there is so much highly processed fake food under the Vegan banner.

But my wish was to direct some thought towards positive developments in nutrition science and away from the psuedo science and myths about protein and good oil and so on. There are some heavy hitters here, you among them. I hope to influence your thinking.

In space no one can hear you wheeze.

Oh and I meant to mention, I have not had a single stone since switching to the Esselstyn/MacDougal type of WPF diet, whereas they used to be an almost monthly ordeal.

Veganism strikes me as too extreme – no animal products like eggs or milk? Vegetarianism is far more understandable.

Personally, I think an omnivorous diet is fine, as long as nutrition and portions are in balance.

It seems to me that debates about this tend to go to extremes. Veganism is unhealthy for a child whose body is still growing. On the other hand, excessive meats/fats can be problematic, especially as people age. If you’re having health issues, switching to vegetarianism, even temporarily, may be an excellent solution. However, that doesn’t mean that all meat is poison.

Unfortunately, there’s not enough clear and scientific information about this particular topic. The public forum is flooded with ridiculous diets pushed by salesmen and ideological commitments to certain lifestyles.

Legumes (beans, lentils, peas) are plant-based sources of protein fit for humans. Spirulina and nutritional yeast are single-cell sources of protein fit for humans, that can grow much faster and be more efficient at producing protein than plants.

Will pass on the insects.

What’s the difference between locusts & shrimp?

One fly’s and the other swims, taste wise one is crispy and buttery and the other seafoody, I prefer the seafoody taste.

Chris Wolfe looks at the possibility of using microbes to provide the animal protein: http://phobosorbust.blogspot.com/2016/05/minimalist-food-supply-synthetic-amino.html

You did notice the 1% efficiency issue so that in effect you were creating a lot of waste liquid to produce these amino acids? This is not going to be particularly useful in mass constrained life support systems.

But that isn’t even the main issue. Human digestion requires more than a liquid diet to remain healthy. So you might as well eat the plant material directly rather than try to grow bugs with nitrogen sources to convert cellulose to create amino acids, unless you are just hoping for supplemental amino acids. But we can recycle indigestible cellulose using other organisms, with a higher overall efficiency, e.g. rabbits, tilapia.

Finally, gut microbiomes are sensitive to diet. We might want to be very careful about such drastic diet changes in case the unforeseen consequences are serious.

There was a microbiome study of the astronauts on the ISS in 2014, but I have yet to find a paper of the results of that study.

One of my favorite subjects. First I heard of this rathab in Barcelona. Would really appreciate any link to papers out of there.

I agree that far too little attention is paid to this work.

MELISSA, and ESA science in general, is under publicized, especially when compared to NASA science. To find papers I usually look at Google scholar, I found this master’s thesis which I have not read:

http://hdl.handle.net/2117/86047

It should be a good point to start considering it is from 2015.

Growing food is an uncertain business. A failure from any one of numerous causes could prove fatal for the crew of a spacecraft in deep space. It might even be problematic in colonies without sufficient backup.

The problem of growing food, but especially cooking, could be mitigated by using artificial g in spacecraft and space stations. As any cook can tell you, there is a lot of extra mass needed for cooking utensils and waste will be produced that has to be collected or disposed of. All this has to be balanced against having pre-packaged/pre-cooked meals that can be made to a high taste specification and easily heated, with low waste.

While in the long term growing food in space makes sense, I think that the efforts to date are more like science experiments than real attempts to develop a usable technology. I would limit much of the work to developing fresh fruit/vegetables that are easily grown as supplements to pre-packaged foods, e.g. tomatoes. It wouldn’t surprise me if spicy fruits and herbs, grown from seed would turn out to be valuable money spinners on commercial facilities as well as locally brewed or distilled beverages). But the effort and extra mass to try to grow food as part of an recycling ecosystem for space based facilities, especially deep space vehicles, strikes me as somewhat ill-advised.

I agree that several of the issues can be mitigated with spin gravity. Unfortunately it has yet to be demonstrated in space, at least on a human scale. The current ECLSS expels mass into space when cleaning human waste thus requiring periodic mass resupply. A more closed ECLSS allows longer autonomous trips to space and is most certainly a necessity for interstellar travel.

Perhaps, but mechanical equipment can fail too. I think growing food in space really comes into its own when you combine it with purging the CO2 and providing oxygen. Then, if you use algae for that, e.g. the spirulina algae – I think you can say that arguably that’s a more robust system than any complex mechanical way of doing it. Even if nearly all the algae die, through some problem of maintenance, you just need a few left, clean the container, and you are ready to go again. While if a mechanical CO2 scrubber or the equipment to make oxygen from water fails, you need mechanical part spares, and if you don’t have those or can’t produce them, you are sunk.

I agree that food by itself is a small part of the mass. But add in the water that’s split to make oxygen, which could be replaced by growing plants in a closed system, with algae as a backup to make sure you have oxygen no matter what, then it’s quite a large part of the mass requirement for a long duration mission.

Surprisingly little is needed to create enough oxygen, especially from algae. Even with plants, then only 13 square meters of growing area per astronaut, and if they produce all their own food, they automatically also produce enough oxygen, and scrub just the amount of CO2 from the air, to close the cycle (because of the way the equations work, the carbon is mainly exhaled as CO2 and only a tiny fraction as feces).

I wrote a blog post about this here: Could astronauts get all their oxygen from algae or plants, and their food also?

http://www.science20.com/robert_inventor/could_astronauts_get_all_their_oxygen_from_algae_or_plants_and_their_food_also-156990

Before suggesting astronauts should live off Spirulina, you might want to try eating it as your sole diet for a while. ;)

Maintaining an algal colony in a bioreactor is not trivial, and if it fails, you cannot easily restart it and wait for it to produce oxygen and eventually food.

Algae don’t process themselves either, you need equipment to harvest and process it to a form that you can even eat. The water that it needs to grow in cannot be electrolyzed for O2 either. All this means extra mass that while fine in a space facility, is a serious mass penalty for spacecraft.

Consider, a person eats about 1 MT of wet food per year. Just 1 cubic meter of water has the same mass, and this must generate the same mass of food that it replaces.

By contrast, we can store that tonne of food, consume it, and at a minimum use the water content (both free and respired) as propellant. Even if that water was just electrolyzed and burned as chemical fuel with an Isp of 450, that would accelerate an equal mass of spacecraft 3 km/s. (And much better to electrically accelerate that water with a much higher Isp).

Humans enjoy eating, and good, tasty food is an important morale booster. Having easily accessible food to cook frees up time from maintaining the necessary food production system. How many people grow all their own food rather than just grow some hobby vegetables to supplement the grocery store source.

When we get to build large space hotels and colonies in space or on planetary bodies with large populations, then it makes sense to grow food locally when you have the manpower to devote to food production and processing and to reduce transport costs. But this idea that we need to recycle life support for trips to Mars and back makes very little sense and seems more like an excuse for not going at all until the system is “perfected”.

Growing food at Antarctic bases is perhaps the model we should aim for – supplementing supplies rather than relying on them.

http://www.spaceref.com/news/viewpr.html?pid=13724

Hi Alex, it’s much less algae than you’d think, because of the light tubes. And you don’t have to eat it. In the BIOS-1 experiments they used inedible algae, but it still was worth doing.The main purpose is to scrub the CO2 and produce oxygen. Producing some useful food is a biproduct. In BIOS-1, 20 liters of algae and water (20 kg) spread over eight square meters of lit surface (using light tubes to increase the surface area) provided all the oxygen for a single person,

The later BIOS-2 and BIOS-3 went on to grow crops like wheat, sedge-nut, beet, carrots, and other crops, ten crops in total in a conveyer like system.

Remember there are no plant diseases or insect pests in space. As with the mechanical methods of scrubbing, of course you’d test it long term in LEO and on the Moon before heading off on an interplanetary voyage. I think myself it would be very unsafe indeed to set off on any interplanetary voyage until we have at least some years of experience of the same systems closer to Earth not needing any resupply from Earth.

Remember there are no plant diseases or insect pests in space.”

Good point! We have the opportunity to keep plants disease free in space. I’m working on a nanobot that tickles anthers. Although a clean strain of honey bees would be interesting.

I don’t think pollination is a major issue, is something that’s done often, hand pollination, and many crops don’t need to be pollinated to form fruit or seeds and as for growing the next generation, many seeds don’t take up much space, or weigh much,so they could just have seeds for the duration if necessary.

The issue for plant pests and diseases would be similar to a commercial hydroponics faculty which do exist. One of the main benefits of them is that they are free of soil born pests and diseases. May still be some things you need to think about, molds for instance, that can be airborne and found in a human habitat. But significantly reduced. They didn’t seem to have any issues with pests in BIOS-3. While with something like Biosphere 2, trying to replicate natural conditions, then it’s much more of a problem and they did have issues with pests.

Actually Scott Kelly did have to contend with fungi during Veg-02. When MELiSSA asked the French caterers for recipes, the idea was to use the sort of material that astronauts would have around rather than industrial processing materials. I know that on Earth spirulina often gets turned into pills, ESA asked for something that used raw or at most dried spirulina. In any case the current ECLSS systems have their limitations: One reason that CO2 is in such a high level on the ISS is that scrubbers do not work that efficiently to drop it to earth surface levels. Also current water treatment systems are not able to process menustral blood, female astronauts take pills so as not to have their period in space. I don’t see the majority of food grown in space any time soon, it will still be packed from earth. The lack of a biological ECLSS is not what is stopping from leaving Earth orbit, more like the lack of a big rocket and the lack of a high level realistic plan to assemble an interplanetary spaceship. Growing food at this point is indeed secondary to engineering challenges

Agreed that food will be supplied from Earth for a long time. However, CD is about, you know, interstellar. So it is encouraging to read your excellent article on the subject. Baby steps, but steps nevertheless. I hope you will follow up as the technology progresses.

I was particularly impressed by the zinnia comeback. It would be a good thing to have fresh flowers about to give that “homey touch” whether its a Bigelow module or an encounter with Rama.

Just a minor correction, actually they used 17 kg per person. Details here:

“We realized this system for the Chlorella population, optimized the physical parameters of the culture and the composition of the nutrient medium, and obtained continuous culture that was only limited by energy – by the amount of the incident photosynthetically active radiation. It produced so much oxygen that 17 liters of the culture spread in a thin layer in the reactor with the light-receiving surface area 8 m2 was enough for gas exchange of a human subject whose body mass amounted to 70 kg. That was the basis for constructing Bios-1, a system in which the sealed cabin with the human subject was connected to the Chlorella reactor Bios-1 (Fig. 1) and the subject stayed there for days, due to gas exchange with the algae, which took up the carbon dioxide he released. .”

http://krsk.elib.sfu-kras.ru/bitstream/2311/630/1/3_Gitelson.pdf

The main advantage for using algae is that it’s only 17 kg per person for a system that both scrubs the CO2 and provides all the oxygen they need + you need solar collectors and light tubes to pipe the light to the algae. But still likely to score over mechanical methods. And as well as that, it’s very reliable. If something did destroy nearly all the algae, you just need a few cells left and you can grow it back again – try doing that with mechanical systems that fail!

Would need to be tested in space but I think it’s promising enough to be worth testing. That the algae is edible, and some of it can be eaten by the crew is a bonus, it’s not a complete diet but they could eat some of it.

Thank God somebody’s on this…Bigalow Aerospace will be launching the inflatable space habitat soon…Later, a three man room will be perfect for a space kitchen…We have to start somewhere…Ten three man rooms tethered to a large central hub and set to rotating…our first agricultural community in orbit…We want to be ready…

This post is a keeper…

Yes! Get those g’s in place. Let the micro-g portion be an optional environment. So much easier to live in a gravity field, which will be important for tourists to be comfortable and lessen the learning curve needed (who needs to learn to use a zero-g toilet for a few days stay?). When the rich toast the “what are the poor people doing now?”, they will want to drink from fine glassware, not a plastic bulb, and be able to smell the bouquet rather than having a fluid swollen head and nasal passages.

I know we’ve discussed this before here but artificial-gravity is such an important aspect for our future space endeavours yet it seems as if it’s being ignored and put off as a problem to be adressed in the future. Yes there are many aspects to consider but the payoff will be huge and enabling.

This is what I like most about this site, we discuss all of the parts of the great journey that we will have to make from propulsion, communications, construction and to food which is what we will need to sustain us all.

And as for meat, I think it will be 3D printed from stem cell cultures.

Print meat? OK, and where we will source the nutrient broth for the cell culture? Plants require N,P,K,C,H,O and micronutrients, animals and cell lines require high level broths with far more complicated molecules. I think meat will more likely come from tin cans than stem cells.

It would be easier to stock the base chemicals and micronutrients than have half a million ‘weighty’ sterilised cans hanging around. There may be the possibility of using plants and bacteria themselves to provide the micronutrients with hybrid plant/animal cellular structures using genetic engineering.

Some animals have managed to do it already,

http://www.darkroastedblend.com/2012/04/impossible-plant-animal-hybrid.html

All we need is these things to taste like chicken and beef and we are made.

The first substrate I learned about as a agronomist was PDA, for Potato Dextrose Agar, which is a substrate for growing fungi. Agar is a seaweed from which we extract the agar substance through processing. While I have not read the papers my understanding is that the nutrient substrate for vat grown meat contains the kind of precursor materials that require complex organic synthesis to organize, do not have a long shelf time and are susceptible to breakdown by cosmic radiation. Much as there has been a long effort to make them vegan, it is still far more efficient to grow an entire animal and slaughter it as opposed to vat grow meat. Tin packaging is relative, NASA actually buys tinned goods and repackages them in plastic to reduce container weight.

Brilliant!

It seems that the algal gene in E. chlorotica’s sex cells could be passed to the next generation.”

We are close to being able to do this in humans…technically, but aeons away in terms of ethics! I am not afflicted with any bourgoise obsession with morality so I say GO FOR IT!

As a general comment, I praise the get-it-done attitude of this poster. The task of getting a viable human population to a planet of another star is a huge one. If we hamper the designers with all sorts of “ethical” and “moral” considerations it will become much more difficult and may be impossible. I always admired the standpoint of Doctor Moreau: “To this day I have never troubled about the ethics of the matter.”

As a hobby homesteader, who often daydreams about homesteading on Mars, I love the topic of closed loop food production. I will be building a greenhouse next season and may have to include an “air lock”. Growing food may be an uncertain business, but we won’t genuinely colonize the Moon, Mars, or anywhere else in the solar system until risk-taking goofs like myself are able to homestead.

The first animal I would include in a “closed loop” system would be red worms. They could compost human waste and non-edible plant parts into plant fertilizer and are themselves edible.

pan fried worms – like crispy bacon?

I wouldn’t get many dinner guests until I upgraded to feeding my red worms to Tilapia or fish in general.

By choosing carnivorous over herbivorous fish you are cutting the efficiency of your food system by an order of 3. You do not want to feed tilapia worms that had eaten plant food, feed them the plants directly

Old army trick… pan fried worms, crushed to powder, add to egg for an omelette.

Cultured Meat is the way to go. NASA first funded it and it will be commercial in 3 years on Earth according to Memphis Meats.

I see a CRISPR future for protein nutrition in space using live animals which can be bred in situ. What’s needed is a tasty new species that’s easy to raise and breed. Probably something in size between rat and small dog, that tastes like beef (not chicken).

Rabbits perhaps?

Or guinea pigs. Both have very high feed conversion rates, with guinea pigs having a slight advantage. I don’t have experience raising guinea pigs but I do raise rabbits for meat and they put on weight very quickly as well. Both are also true herbivores (unlike chickens), are fairly clean when alive and when it comes time to slaughter create much less waste than chickens.

Wait, the higher plant component is a source of food AND water? I’d expect the crew to be a source of water, (It’s a major waste product of our metabolism.) and the plants to be a water sink.

Also, I’d think twice about designing a life support system which requires the crew to consume insects as a significant part of their diet. Insects are arthopods, and are as capable of triggering shellfish allergies as shrimp. Pity the poor crewman who, a year out, starts to find his mouth itching after he eats his fried crickets, and no other source of protein on board.

Plants are big water pumps: they take water in their root and transpire at the leafs. Higher plants are source of water in the sense that we collect the transpiration and condense it.

Apparently freeze dried shrimp is a very popular plate with astronauts because it is the only food that can goes through the freeze drying process and keeps its taste intact. I have the feeling that shrimp allergies are a disqualification to becoming an astronaut

I have no doubt of that, the problem is that shellfish allegeries typically first appear comparatively late in life; My sister’s appeared in her late 30’s, I believe, mine in my late 40’s. And then they proceed to get worse every time you’re exposed.

The fact that the astronaut didn’t show any signs of a shellfish allergy doesn’t, unfortunately, mean that they won’t develop one in the course of a multi-year flight.

YES, SO pre-select crews for their allergies.

I think the point is that people can develop allergies in adult life without any prior warning.

While there’s a tremendous amount here to digest (no pun intended). There is to be said for this a lack of consideration of a nonbiological route for food stocks. That is, as anyone considered the idea of using a totally chemical process to synthesize the requisite phytocompounds , proteins, and basic starches through a total chemical synthesis? It would have the advantage that you would not have extraneous parts of plant and animal parts to dispose of, but would permit reconstitution chemically of waste products back into strictly chemical but edible foodstuffs.

After all, were talking about astronauts here, not individuals who are going on these missions to have the equivalent of a carnival cruise type of experience. If you volunteer for it, you probably should be roughing it anyway and this might be a best way to go.

I assume what you think needs to be done is just reproduce amino acides, a glucose, a fat or oil, possibly cholestrol and take along capsules for micronutrients, as synthesizing the vast array of compounds in food would be impossible. The problem is that chemical synthesis is inefficient, even apart from the equipment to do so.

The choice is growing food biologically, even if that means growing cells for processing into solid foods, or bringing pre-packed food. Each has its pros and cons depending on the situation and context.

The great advantage of growing food in space will be to prevent a great number of parasitic organisms from causing plantdicease . This may seem obvious , but it will not be a simple process at all .

Some plant virus can enter the plant’s DNA , and lie dormant there until an external factor trigger them to start multiplying again . Other single celled parasites can be passed on from one generation of plants to the next in ways we know very little about , and will be present in unknown quatities in comercially avaiable seeds .

Until now there have been no comercial reason to deal with theese problems , beacause any sterile seeds would be contaminated in seconds whereever you would try to grow them .

In order to obtain completely sterile , and therefore safe seeds , it probably will be necesary to invent a whole range of new tools and procedures just to get started .

It may also be difficult to isolate the growth media from contamination delivered by humans …..we carry thousands of more-or -less unknown species of bacteria , virus’s and fungi in and on our bodies , and any number of these could VERY quickly adabt to attacking our sterile plants …

In short we have to Re-Invent agriculture in a space environment IF we want to achieve the full potential of parasite-free growth …it may be necsary to work in conditions similar to a high-risk biological warfare-lab !

Plants are quite susceptible to viruses and we do have both the wish and the methodology to remove viruses from the genome. Worse part is that unlike animals, once infected plants cannot remove the viruses. The usual ways to remove viruses from multiplying plants is meristomatic multiplication, where we select cells from the meristome which is at the edge of the plant’s eye and does not have viruses and cell culture in general. Especially for potatoes removing viruses is a sector with lots of knowledge and a long tradition because potatoes reproduce commercially only asexually. For asexually reproduced plants in general virus health is a major issue.

Completely sterile habitats are dangerous and unhealthy. Not only do we need symbiotic bacteria to survive, if a pathogen enters a sterile environment without competitors it is far more lethal.

Rabbits it is then :)

So , should we give up on realising the full potential of parasite-free agriculture ? Is this idea another ‘utopian dream’ disconnected from reality ? Is there no logic in separating the non-sterile humans from the potentialy sterile agricultural environment ? It seems to me that both strategies are worth investigating …at least until much more is known about the whole area .