Centauri Dreams returns with an essay by long-time contributor Alex Tolley. If we need to grow a much bigger economy to make starships possible one day, the best way to proceed should be through building an infrastructure starting in the inner Solar System and working outward. Alex digs into the issues here, starting with earlier conceptions of how it might be done, and the present understanding that artificial intelligence is moving at such a clip that it will affect all of our ventures as we transform into a truly space-faring species. Under the microscope here is a company called SpaceFab, as Alex explains below, and the potential of ISRU — in situ resource utilization. Emerging out of all this is a new model for expansion.

by Alex Tolley

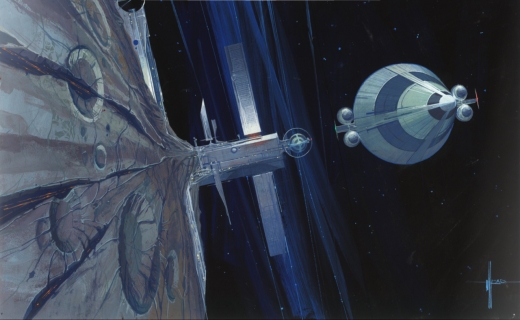

“Asteroid Facility” – Syd Mead

To sail the heavens and reach the stars is extremely expensive. With the technologies we can currently envisage, Earth’s GDP will need to be orders of magnitude larger to support a starship program. Unfortunately, the Earth is likely to hit environmental and economic limits well before we reach the necessary size of a starship building GDP. One solution is for humanity to expand into the solar system to grow the economy with the vast resources available out there [5]. Science fiction novels are replete with tales about self-reliant belters extracting wealth from the asteroids, while followed by adventurers, gold-diggers and chancers, that recapitulate the myths of the “Old West” and the US’ manifest destiny [1].

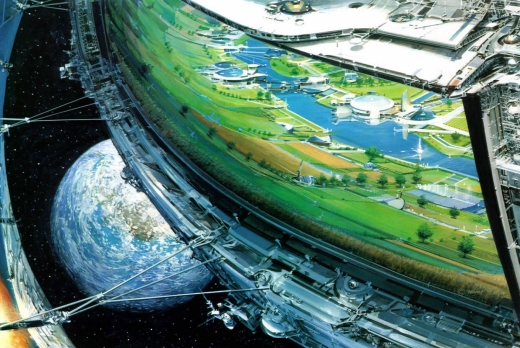

Space Habitat – John Berkey

By the late 1970s, establishing space colonies and selling solar power to Earth [2] was the idée du jour. Allen Steele popularized that vision, regaling us with stories of men and women living and working on the high frontier [3]. In reality, the cost of transporting and housing space workers is astronomical compared to those of ocean rig workers whose jobs those high-frontiersmen emulated. An economy supporting a wealthy, post-scarcity civilization living throughout the solar system and able to support starship exploration became more fanciful, and we focussed on scaling back our starship ambitions with 1-gram, laser-propelled, sail ships that might launch half a century hence.

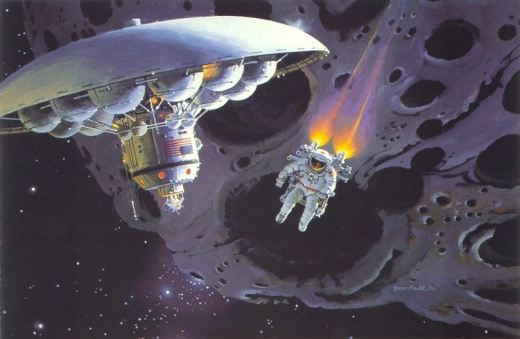

Exploring the Asteroids – Robert McCall

Exploring the Asteroids – Robert McCall

While the prospects for humans in space dimmed somewhat, a renewed flowering of developments in AI and robotics burst onto the scene with capabilities that astonished us each year. On the endlessly orbiting ISS, while astronauts entertained us with tricks that we have seen since the dawn of spaceflight, autonomous robots improved by leaps and bounds. Within a decade of a DARPA road challenge, driverless cars that could best most human drivers for safety appeared on the roads. Dextrous robots replaced humans in factories in a wide variety of industries and threaten to dramatically displace human workers. DeepMind’s AlphaGo AI beat the world’s champion GO player with moves described as “beautiful” and well within the predicted time frames. In space, robotic craft have visited every planet in the solar system and smart rovers are crawling over the face of Mars. A private robot may soon be on the Moon. In orbit, swarms of small satellites, packing more compute power than a 1990 vintage Cray supercomputer, are monitoring the Earth with imaging technologies that equal those of some large government satellites. On Earth we have seen the birth of additive manufacturing, AKA 3D printing, promising to put individual crafting of objects in the hands of everyone.

What this portends is an intelligent, machine-based economy in space. Machines able to operate where humans cannot easily go, are ideally suited to operating there. Increasingly lightweight and capable, and heedless of life support systems, robotic missions are much cheaper.. How long before the balance tips overwhelmingly in the machines’ favor? Operating autonomously, advanced machines might rapidly transform the solar system.

In a previous post, “A Vision to Bootstrap the Solar System Economy” [4], I looked at an academic paper that laid out an idea of self replicating robots that would start harvesting lunar resources and eventually expand operations out to the asteroid belt. The power of exponential growth to bootstrap such a system was clearly evident, allowing a relatively tiny investment to create a huge manufacturing capability of staggering size within a short time with growth rates far exceeding our current human-based economies. An interesting idea and vision, but was anyone going to consider developing a business using that approach? A new company, SpaceFab, shares a similar vision. The founders want to create a fleet of mining and fabrication robots that will extract raw materials from the asteroids to create refined commodities and products in space, including building more robot miners and fabricators. A grand vision, but how do they envisage it being done?

While the original idea of asteroid mining was to extract the non-volatile resources, especially the high value platinum group metals [5], more recently the focus has shifted to volatiles, primarily water, for life support and chemical rocket fuels. SpaceFab however, prefers the extraction of the more abundant iron and nickel, whose current value in space is principally their launch cost. Their argument for this focus is twofold. Firstly, water is relatively rare in most near Earth asteroids (NEA) and therefore likely to be more difficult to extract from those bodies. While common in asteroids beyond the frost-line or in dead comets [10], the delta v cost is high and journey times much longer. Conversely, metals are far more accessible inside the frost-line with NEAs, reducing both the cost to acquire these metals and the mission cycle time. Secondly, SpaceFab is looking to extract iron and nickel using simple, lightweight and low-cost processes like magnetic collection of material, and induction heating to melt and refine the metals. Their view is that the path to profitability is faster with this approach than prospecting and extracting volatiles.

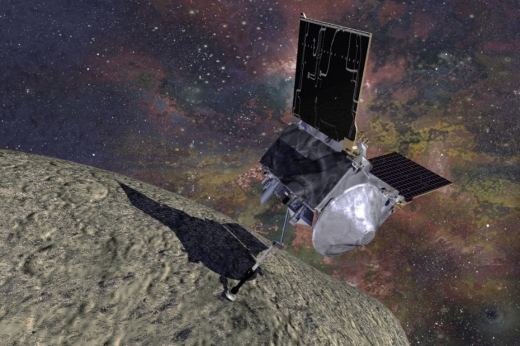

The OSIRIS-REx mission is NASA New Frontiers mission to return a sample of an asteroid (101955 Bennu) to the Earth. Mission cost is approximately $800 million (excluding the launch vehicle.). – Lockheed Martin

SpaceFab believes that they might get a sample return mission to an M-type asteroid within 10 years and a mining craft 5 years later. Their design target is for a craft just 1 MT in mass (about the same size as OSIRIS-REx), and consists of an ion engine, rock scraping tools for extracting material, and some form of electrical induction heating to produce refined ingots. When sufficient extraction is achieved those refined ingots could then be used as feedstock for space manufacturing. While apparently ambitious, the concept of small craft to mine asteroids has been developed by Calla, Fries and Welch and was presented in two papers at the IAC in 2017. Their craft were designed to be less than 500Kg. Water in close by NEAs was their objective based on their analysis of extraction methods which indicated using microwave thermal heating. Teleoperation from Earth was assumed and therefore an NEA within 0.03 AU was preferred. The small size combined with a swarm model for redundancy was the most economically modeled approach to provide a large and early return on investment [15,16].For robotic craft on deep space missions, high Isp electric engines reduce costs, as the lower propellant mass means lower launch costs. To keep costs low, SpaceFab intends to use off-the-shelf ion engines that may be augmented by their ion accelerator technology (patent pending) that they claim boosts Isp several fold. With the Dawn mission spacecraft’s NSTAR ion engine having an Isp of 3100s, Spacefab might hope for an augmented Isp of up to 10,000s. The addition of this accelerator unit and the solar panels to power it should increase the mass ratio performance of the craft.

So far SpaceFab’s approach seems similar to other schemes to mine asteroids. Where SpaceFab’s vision really differs is the use of ISRU (in situ resource utilization) for construction of onsite mining and fabrication tools. Rather than hauling out machine tools to an asteroid to extract and fabricate components, SpaceFab plans to reduce the mining craft’s mass, and therefore cost, by building many of the machine tools for mining and fabrication using local resources. It is just one step further to replicate the whole craft. This model of self replication of much of the mass of the machines is similar in concept to the robot bootstrapping paper and promises to open up exponential mining and fabrication possibilities, while making the owners quite wealthy.

Most asteroids are too far away to allow teleoperation of the sort that would work on the Moon or with close NEAs. This rules out complex manufacturing guided by human controllers. The intelligence needed to prospect, mine and process ores must be local. Beyond some human oversight, these robot mining craft and fabricators will need to be highly autonomous. This requires advanced AIs. While we are not close to that goal today, the rapid pace of development of AI software and specialized chip hardware promises to make this a reality sometime in the projected time frame. Such craft will be able to navigate to a selected asteroid, prospect it, extract and refine metals, and then fabricate machine tools and manufacture components. SpaceFab believes that such craft could even provide a “manufacturing on demand” service in space. On Earth we have seen the birth of additive manufacturing, AKA 3D printing, promising to put individual crafting of objects in the hands of everyone. The technology is already being tested on the ISS to reduce the number of spare parts that must be shipped.

Fabrication, even self-replication, is no longer a science fiction concept. Nasa has a “FabLab” program to investigate the best ways of using that technology to facilitate spaceflight as a result of its success with 3D printing experiments on the ISS. Neil Gershenfeld’s lab at MIT has designed a method of robotic self-replication suitable for use in space. The current proposed system can fit inside a CubeSat [14]. The basic technologies needed for SpaceFab’s vision are already in place, just requiring further development.

The eventual goal of robot miners and fabricators producing commodities and goods at a fraction of today’s prices, via massive supply expansion, may face some short term obstacles. Low launch costs spearheaded by NewSpace companies like SpaceX could make placing raw materials in space cheaper than space mining, for cis-Lunar infrastructure. However, space fabrication of components in situ is a useful goal, regardless of the raw material source. In the 1980s, K. Eric Drexler intended to manufacture ultra-light, aluminum solar sails in space. T. A. Heppenheimer described manufacturing trusses for solar powersat arrays using relatively dumb, machines bending and welding rolled sheets of aluminum. Grumman Aerospace had a working prototype “Composite Beam Builder” by the time Heppenheimer’s book [5] was published. More recently, NIAC has funded space fabrication projects using more sophisticated robotic builders.

At some point, regardless of cost, the sheer volume of resources for expanding the economy will require sourcing from space to overcome the Earth’s limitations. Robotic mining and fabrication will then become the norm. As with newly industrializing Earth-based economies, initial fabrication may be for simple, low value added, bulk commodity products, but eventually as capabilities increase, higher value added manufactures will be possible.

Although initially limited by key components like advanced computer chips, over the long term, self-replicating craft would evolve into Von Neumann replicators. Philip Dick invented the term autofac for factories that could construct themselves from seeds and self replicate [6]. While Von Neumann machines are just self replicators, autofacs also generate outputs, much as honeybee colonies also produce excess honey. Such self-replication and fabrication infrastructure could produce a vast range of products for the solar system economy.

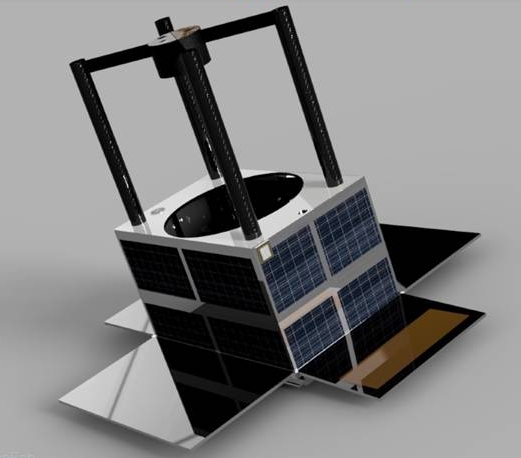

SpaceFab’s Waypoint Telescope – engineering mockup.

To reach the goal of space mining and manufacturing without the deep pockets of a Deep Space Industries or Planetary Resources, SpaceFab intends to enter the orbital satellite observation market. They have designed a low cost, high resolution (1 meter ground resolution) telescope that can be used both for astronomical and Earth observation purposes, using a variety of imaging sensors and filters that offer the range of imaging outputs suitable for both markets. Currently they are crowd-funding their initial prototype telescope which will be followed by a flight ready telescope for a 2019 launch. By launching a fleet of such telescopes, they expect to penetrate this market by offering the lowest price imaging and analysis services.

This observation service would then produce the profits needed to develop the asteroid mining craft and bootstrap the space fabrication business. Interestingly, SpaceFab currently has no intention of using these observation satellites to prospect for suitable asteroids as DSI intends, but rather to use existing information to enable a mission to an M-type NEA. As this information will not be detailed enough for detecting higher quality ores, the spacecraft will need to be smart enough to do their own prospecting on arrival at an asteroid. SpaceFab speculates that in the near term, the value of fairly pristine asteroidal material may be higher for research than its commodity price and may offer a faster path to early profitability.

Once mature, self-replicating fabs promise a future that has vastly expanded horizons and implies a post-scarcity economy. Once such seed factories become ubiquitous, there is no reason why they could not venture to other solar systems and replicate there. Even if slow, perhaps travelling at 1/100th c, they would reach the nearer stars in half a millennium, creating all the materials and habitats for humans to occupy. This is the model that Asimov’s “spacers” envisaged for themselves [7], their robots preparing the way for them to follow. The colonization process would be with a wave of machines preparing star systems for the following human starships.

It is a dazzling future to contemplate if it unfolds this way.

References

- Anderson, Poul. Tales of the Flying Mountains. Tom Doherty Associates, 1970.

- O’Neill, Gerard K. The High Frontier: Human Colonies in Space. Morrow, 1977.

- Steele, Allen M. Sex and Violence in Zero-G: the Complete Near-Space Stories. Meisha Merlin Pub., 1998.

- Tolley, Alex “A Vision to Bootstrap the Solar System Economy” https://www.centauri-dreams.org/?p=36963

- Lewis, John S. Mining the Sky: Untold Riches from the Asteroids, Comets, and Planets. Addison-Wesley, 1998.

- Heppenheimer, T. A. Toward Distant Suns. Stackpole, 1979.

- Dick, Philip K. “Autofac.” The Collected Stories of Philip K. Dick, Subterranean Press, 2010.

- Asimov, Isaac. The Robots of Dawn. Bantam Books, 1994.

- SpaceFab http://www.SpaceFab.us/

- Graps, A et al. “In-Space Utilization of Asteroids – Answers to Questions from the Asteroid Miners”, ASIME 2016: Asteroid Intersections with Mine Engineering, Luxembourg. September 21-22, 2016. arxiv.org/abs/1612.00709

- Brophy, J., et al. “Asteroid Retrieval Feasibility Study” (2012). Keck Institute for Space Studies, Caltech, JPL. kiss.caltech.edu/final_reports/Asteroid_final_report.pdf

- Welch, C., et al. Asteroid Mining Technologies Roadmap and Applications (ASTRA)” (2010) , International Space University isulibrary.isunet.edu/opac/doc_num.php?explnum_id=73

- Mazanek, D. “Asteroid Redirect Mission Concept: A Bold Approach for Utilizing Space Resources.” Acta Astronautica, Pergamon, 23 July 2015, www.sciencedirect.com/science/article/pii/S0094576515002635.

- Langford, Will, et al. “Hierarchical Assembly of a Self-Replicating Spacecraft.” 2017 IEEE Aerospace Conference, 2017, doi:10.1109/aero.2017.7943956.

- Calla, P., Fries, D., Welch, C. “Analysis of an Asteroid Mining Architecture utilizing Small Spacecraft”, IAC 2017

- Calla, P., Fries, D., Welch, C. “Low-Cost Asteroid Mining Using Small Spacecraft”, IAC 2017

I think there are two resources for which there will be bottomless demand: Energy and CPU cycles. Other resources will be valuable insofar as they play a role in enabling the former two. Autofac manufacturing has great potential insofar as it could churn out space-based solar panels at scale. These wouldn’t need to beam down their power to Earth if vast racks of power-hungry computers were also in space. Most organizations that have need for supercomputing don’t require low-latency connections to those computers: a supercomputer in the asteroid belt is just as good as one in your basement for the purpose of simulations/modeling, machine learning, coin mining, or really most things that supercomputers now do.

Once we think seriously about autofacs, we confront demand saturation points in just about everything we value. What if a mountain of platinum ingots fell from the sky? Nothing transformative. The demand for catalysts etc. would saturate instantly, and the rest would end up in cheap Chinese watches sold on eBay. Maybe we’d start making soda cans from it. (I’m reminded of Napoleon’s aluminum flatware, which had more value and prestige than forks and spoons of pure gold.)

It’s different with computing and energy: As more comes online, it’s guaranteed to find buyers willing to pay a decent price, ad infinitum. A part of the reason is that it drives processes that themselves generate value. You could say it’s self-catalyzing.

Now I know many people here picture autofacs mainly building places for people to live in space, and yeah, that will happen. But it’s really easy to overestimate the demand for this. For human life, space sucks and the Earth is amazing. There will be weirdos who want to live on Ganymede or on the moon or under the sea, but they will not number more than a handful of millions – a kind of rounding error. Human fertility is leveling off, and the Earth will be even nicer in the future than it is now.

Space science will need material and manufacturing, but it too saturates quickly. Once we build a few square kilometers’ worth of optical telescopes – which will be amazing – demand for yet another one, or another damn orbiter of Neptune dedicated to studying magnetic field inhomogeneities, will not be high.

Converting the system to”computronium” is one future that has been envisaged. Charles Stross’ “Accelerando” is a great fictional example.

I second Alex’s thoughts on Accelerando and really appreciate the science fiction references he used here — they’re all exactly on point.

A full response to this would require a post. While the Earth is indeed far more hospitable than anywhere else in the solar system, possibly even the universe, there are sticks and carrots to attract offworld living.

Firstly, climate change, biodiversity declines, and ecosystem collapses are making the Earth we once knew less attractive and more dangerous. The rise of megacities to contain the rising populations are unpleasant places to live unless you are one of the wealthier inhabitants. For most, life is rather grim. The option to live a more comfortable, safe, and possibly leisurely life in a space habitat might be quite attractive to many.

With unbounded construction, life might be quite pleasant with no restrictions on procreation. The design of such habitats is as likely to be as diverse as habitats on Earth. Historically people have been happy to live in one small place all their lives. OTOH, as a Westerner, I have known the restrictions of living on a small, but beautiful island, including the problems of “rock fever” that demand to escape to wider landscapes. I know that without some possibility of frequent trips to other habitats or even larger celestial bodies, including Earth, living in an O’Neill Island One is not for me. But for many others, such a life might be quite preferable to the one they have now, with the opportunity to travel to a huge number of different habitats whose combined surface area would dwarf that available on Earth.

As for those remaining on Earth, we are constructing multipurpose buildings that one need never leave, and soon arcologies to create attractive enclosed landscapes and dwellings that also one might not leave except for vacations. Those environments for the wealthier classes will establish the conditions that we will likely replicate in space for the same clientele. Like expat duty today, the package might include annual trips to vacation spots on Earth.

Where in space is as comfortable for human life as the middle of the Sahara, or on the Himalayan plateau, or on some random ice floe near Antarctica? All these places have bio-optimal gravity, the protection of a sweet ionosphere and ozone layer, 24 hour days, and you don’t die instantly if your house springs a leak. You suggested that you might want to go to space if … you want to get away from cities? But you do realize that there are many places on Earth where no one will find you. And hermits are real. Sure there will be a few in space one day, but are you really projecting on future people the expectation that they might want to be hermits en masse? And even if they do, why space hermits?

Your post also has other strange and IMO indefensible ideas, like the one about constraints to fertility. I’m not saying that everyone in the world is having exactly as many children as they want. Many women in developing countries still have more than this. But with greater education, women everywhere choose to have fewer kids, an effect which will soon cause the Earth’s population to level off and probably start declining. In the West, nobody is constraining our fertility, and many countries are working hard to promote it (grants to Danes who get pregnant on vacation, etc.). Did you mean to suggest that in space (say in big habitats) we should expect human fertility to be higher than in big empty countries like Russia or Bolivia? Why would that be? People are overwhelmingly choosing to have smallish families and to congregate together. Urbanization is the biggest story the present human era. Again, nobody is chasing people from their farms. They leave because they now can.

Everything I know about human nature tells me that we will have a Libertarian Freetopia floating in the sea long before we set up substantial colonies off Earth. Maybe some nasty cults that that really need to dodge terrestrial laws will have a reason to relocate to Mars, but who else? Do you also think that people are dying to live in Antarctica, but international treaties are foiling their plans? We used to think that humans will be needed in space to work in factories. Now we realize that those jobs will be automated. Again, a few poor souls will be out in the belt to oversee mining operations (low latency is needed for troubleshooting all the robots and maybe some telepresence), but I expect them to live much like scientists do now in Antarctica.

I know that many people want to go to space, even to die on Mars. But that’s just because we want the adventure. One upon a time, people risked death to get to the South Pole. But now, I can’t think of one person who would give up even a year’s wage to go. We should expect every place in space to become like the South Pole in terms of people’s longing to live and die there. Once a few thousand people have done it, it will seem banal and just a bad idea, like living on a boat or something. And of course, compared to even the South Pole, Mars is a shithole in terms of habitability. These are my reasons for thinking that at least until we become able to go interstellar, off-Earth colonies will host a vanishingly small proportion of humanity.

“Where in space is as comfortable for human life as the middle of the Sahara, or on the Himalayan plateau, or on some random ice floe near Antarctica? ”

Anywhere with a properly built habitat, of course. Humans can’t survive on most of the Earth year round without protection, space just requires more protection.

” People are overwhelmingly choosing to have smallish families and to congregate together.”

I’m always a bit puzzled by these discussions that proceed as though Darwinian evolution doesn’t apply to humans. It’s not *everybody* who’s failing to have enough children to replace themselves. Some people have no children at all; They’re removing themselves from the gene pool. Some people have only one child; They’re, (We’re) removing ourselves from the gene pool, too, only not as rapidly.

Then there are people still having larger families. And their offspring are a disproportionate fraction of the next generation.

The implications are obvious. We’ve encountered a social change that causes most people to not have enough children. We’ll have evolved our way out of it a few generations hence, and have an expanding population again. Imagining a future where human populations don’t expand, even keep contracting, isn’t soundly based on what we know of evolutionary theory.

In the developed world, the number of children a couple has is a choice that may well be dictated by financial cost. It certainly was in historic times and appears true today.

Malthusian constraints will limit large children families, even if the factors of education, healthcare and prosperity don’t.

However, all things being equal, your overall point is correct.

In my experience it’s not so much that people in a developed nation can’t “afford” to have 3 or more children, so much as that they don’t want to make the lifestyle sacrifices that are necessary to do it. Infrequent vacations, a smaller home than otherwise, making do with used cars and few fancy toys. Almost everybody today could afford large families if they were willing to make do with a 1950’s standard of living.

So it’s really a question of priorities, not capacity.

Really, the biggest thing driving modern 1st world societies towards small families is the existence of government run pension systems for the elderly, like Social Security. In societies without such pension systems, it’s understood that children are an investment in your future, that having prosperous children around to support you in your dotage is a necessity if you don’t want to have a nasty and short old age.

Public pension systems don’t actually change this; They still require those children be born, so support the current generation in their retirement. But they make of the next generation a *commons*, breaking the link between individual production of children an one’s own state in retirement. And, of course, goods with socialized benefits and individualized costs are always under produced.

You could see, as a result of those who don’t have children not passing on their values, a cultural change in favor of having more children at the expense of lifestyle. You could also, after the current system craters, (As it’s likely to do thanks to that under-production of children.) adoption of more family friendly policies just as a matter of subsidizing an underproduced good, children.

Anyway, I do not anticipate the “demographic transition” enduring for more than maybe one or two more generations, because it’s not a stable situation.

Fertility in the West in unusually low at the moment for various reasons that would require a whole post of itself, but that include falling incomes and our bloated governments; this is unnatural and unhealthy and it is changing – suffice it to say, the global population is going to continue to expand indefinitely unless it encounters resource constraints. This is why we need a new frontier on Mars; humanity needs a frontier to keep its moral character and to maintain and expand freedom.

Amazing is any place humans choose to make so for themselves. Your comment is a non-argument.

Also, all this stuff about saturated markets; it’s not all that simple. As economies expand, so does demand and then there is the increased cost of transportation.

Once the human economy expands into space there will be near infinite demand for resources and at some point the population dwelling beyond Earth will outnumber those living on the home planet.

Your comment reads a little bit like the fabled manager of that patent office who closed his doors in the very early 2oth century because ‘there is nothing left to invent or discover.’

That thought is always wrong. Always. And it is also dangerous, because it produces an inward-looking attitude, which leads civilisations to stagnation and disintegration.

The idea that people will be using digital currencies in the space economy is absurd – these currencies are a fad, a speculative mania that will crash and disappear over the next few years (consult economist and investor Peter Schiff on the underlying reasons for this). No, gold and silver have always been money (notwithstanding the current period of fiat currencies) and they will continue to be so, providing another layer of demand for asteroid resources.

In addition, computing demand is underpinned by a real, physical economy of physical products and processes. So your two arguments about the growth of computing demand and energy and a levelling of the real economy, are not compatible and are self defeating/oxymoronic.

This is just a guess, but it may be easier to build large quantum computers with long decoherence times in space than building them on Earth. The excellent vacuum in space makes it easier to use molecular beam epitaxy to make high quality devices, for instance. It should be easier to keep circuitry at temperatures below 100 degrees Kelvin just with passive radiation.

The vacuum of space might not be the best place to put computers, as it is pretty hard to give off heat in a vacuum. Autofabs would also enable the automated manufacturing of giant radiator panels on multi-square kilometer scales, but this might not the most efficient way. Titan is a perfect place to put computing resources because its dense, cold atmosphere will help speeding up the computing processes and giving off the waste heat. Its insulation is low, and its haze is thick, making solar power less practical, but it has lots of hydrocarbons that can be used as an additional energy source. Solar power can still be used on the other icy moons that have no atmosphere to extract oxygen from water ice, then this oxygen can be shipped to Titan to be combined with the hydrocarbons for energy storage and generation. Greenhouse gases won’t do much harm on Titan, which has already plenty of methane in its atmosphere.

I found this article on quantum computing: https://futurism.com/want-to-build-a-quantum-computer-heres-a-blueprint/ .

“The team’s blueprint features an innovative design that allows actual qubits to be transmitted between individual quantum computing modules. These modules, instead of being connected via fiber optics, rely on connections generated by electric fields which transport ions from one module to another … They are intended to be built alongside individual sophisticated vacuum apparatus and integrated quantum computing silicon microchips where the ions are stored using electric fields. ” I have also read that quantum circuitry will work better at temperatures approaching absolute zero. And perhaps one of the X-37 missions had a quantum communication, computing, or encryption experiment, and the mission ended when the liquid helium ran out.

Thank you Randy, very interesting article. I think very cold temperatures such as those found on Titan could indeed help to generate the ultra-cold temperatures needed to slow down quantum decoherence.

If you haven’t see this video, it might be of interest: Colonizing Titan.

https://www.youtube.com/watch?v=HdpRxGjtCo0

Alex, this is an honour to have a reply from you. I had a look at this video, and I’m amazed that it also brings up the idea of building a super-computer on Titan. Maybe that’s how we will end up using Titan: as a computer-moon.

by ‘insulation’ I meant ‘insolation’ (sunlight power received per unit area on a horizontal surface).

Fuel cells using platinum catalysts would become dirt cheap, facilitating electric transport for all types of vehicles, including aircraft. Not transformative, but a definite improvement.

What if a mountain of diamond was available? c.f. Stephenson’s “The Diamond Age”.

Obviously, if we remove supply constraints, prices fall toward zero. That also means that economics must change, as the capital investment will no longer secure returns. If however, the economy no longer requires capital, but needed commodities and products just rain down from the sky, the general standard of living will absolutely increase for everyone. The problem might then be overconsumption and waste disposal. I think Fred Pohl and C.M.Kornbluth wrote a novel about that.

Dr. Smith would totally lose it.

Yeah but we’re not going to have electric cars with fuel cells. They will have batteries. And electric cars will massively drop the global demand for platinum. See this link: https://www.reuters.com/article/us-platinum-demand-automotive/platinum-demand-faces-massive-impact-from-electric-car-growth-ipmi-idUSKBN19X21V

Which makes platinum even less valuable as a mining target. It may be that fuel cells, even those much cheaper than current ones have lost their window of opportunity. Bear in mind that batteries have far lower power densities than fuels, so fuel cells should be a better bet for long range. The problem for current FCVs is a lack of refueling stations and the problems of storing H2 in fuel tanks. The former is fixable. So far hydrogen storage mechanisms are relatively poor, reducing the effective energy density of hydrogen as a fuel.

“water is relatively rare in most near Earth asteroids (NEA) and therefore likely to be more difficult to extract from those bodies” – As you probably remember, according to Lewis a large fraction of NEAs are extinct comets, whose ice and/or hydrated minerals should still be there, under an insulating layer of regolith.

The key point made by Lewis was that, by extracting propellants, robotic miners could refuel themselves with a fraction of their own product, thus exponentially increasing the amount of product delivered to Earth orbits for a fixed initial launch mass. So far as I know, this prospect is still valid.

Stephen

Oxford, UK

I thought that too, but reference 10[not certain] pours cold water on that scenario. I hope the authors are wrong, but the claim is that despite the insulating dust layer, the lifetime of the core water is relatively short. If so, the number of such bodies is likely low and may be difficult to identify as different from rocky asteroids.

Reference 10, Q14: What conditions would permit the presence of free water ice on an NEO (e.g., on an extinct comet)? Answer (summary): “Ice stability very T-dependent – Need surface T ~ 170 K for km-scale burial stability. Temperature way too high for NEOs, 7% albedo at 1 AU: Tavg ~ 280 K”

There is water available, but probably you’d have to bake it out of clay. So first step is to find a clay bearing asteroid, then send a processing plant.

From ref 10. Here is the relevant text:

Thanks, guys, interesting discussion. It seems the possibility of hydrated minerals on NEOs is still open. But in the end we really need ground truth from asteroid prospecting spacecraft. A detailed survey of a representative sample of these bodies may take quite some time to appear, so maybe best to plan without NEO-derived water supplies for the present.

Stephen

I look forward to reading your essay later, however having read only the first sentence I felt the compulsion to comment. Regarding expense, I am of the opinion that ai driven automation will eventually render the concept as it exists today while not defunct, then surely of less relevance. Once the manufacturing economy is completely automatable, from primary resource gathering to advanced production, cost equations will no longer be made in dollars and cents. I don’t see why it would be a stretch to envisage various ai driven seed bases gathering, producing, assembling, exporting and expanding autonomously. Energy needs achieved through the same methods and stemming from solar, or other locally appropriate technique. Even primary research and project conceptualisation could be executed by advanced ai. Whether stationed in a deep gravity well or in free space makes little difference. The greater question is in who’s hands, if any, this new capacity will lie. Predicting the speed of the ai driven macroeconomic revolution is difficult, but I don’t currently see insurmountable hurdles that would render it impossible.

What we want to do is provide a manufacturing service where people would send us their CAD designs and we would have our factory build things for them. SpaceFab is a US based company with US owners, so we think the SPACE act of 2015 allows us to build and own the factories made from asteroid material. What’s not clear is who actually owns the items we build. If you are a US citizen, then probably you would own the items we build for you. Would you then be responsible for what you do with your items? What if you are not a US citizen? What if we build a habitat for you, can you declare it an independent entity, like FreeSpaceLandia? What if you, as a customer, are anonymous, just an email address and you pay with Bitcoin?

We are entering a new region of law with few precedents to guide our expectations with regard to property ownership in space. Can a country on earth, or even a group of countries, legitimately dictate the law that applies in a region completely outside their own borders?

We have an international treaty that applies toward the protection of Antarctica from commercial exploitation. We also have a ‘law of the sea’ that is widely recognised in regard to operations and salvage rights in international waters.

As touched on in the article, what autonomous rights are likely to be respected by nation states if a Libertarian Sea-topia began commercial operations in open waters? What rights and responsibilities would be incumbent on the governments and international corporations trading with that Sea-topia? I think it very likely the same answers would apply to commercial operations in space; the primary difference being the increasing difficulty of the enforcement of state law on extra-territorial regions of space.

Certainly countries can arrive at mutually agreed treaties that govern the scope of their activities in an unclaimed region. But why would this restrict, for example, international corportations or countries not party to such agreements? And what about the native rights of those future souls who may be born in those regions and establish an independent existence there? This theme was explored of course in Heinlein’s ‘Stranger in a Strange Land.’

Ultimately, I believe that the attempt to implement extra-territorial law will be recognised as merely a presumptuous form of neo-colonialism. History teaches us that this will not be accepted, and if forced, will result in considerable blow back. Consider ‘The Moon is a Harsh Mistress.’

“Can a country on earth, or even a group of countries, legitimately dictate the law that applies in a region completely outside their own borders?”

Can they legitimately dictate the law that applies in a region completely *inside* their own borders? “Legitimacy” isn’t the question, capacity is. If they lack the capacity, who cares if they have the legitimacy? If they have the capacity, what good does the lack of legitimacy do the people in that region? They must, perforce, obey anyway.

The problem with seasteading has always been that there’s no place on Earth where the existing governments lack that capacity. And they’re not interested in allowing any new entrants to the country game. So, sooner or later, they take you out.

They’re probably not going to be interested in allowing new entrants out in space, either. The chief difference is that in space you have the potential to get far enough away from existing powers to make bossing you around infeasible.

Nobody is going to win their independence in space until they’re either too powerful or too far away to boss around.

I think that consideration alone is enough to support the case there will be enough people motivated to emigrate off-planet, despite the difficulties and challenges.

Yes, interesting stuff. Somehow I picture autofacs would first spread in space, for two reasons: One, I’m sure some lobbyists would buy enough politicians to prevent it on Earth. In space there are no nimbys, no congressmen and no luddites yelling about how machines took their jawwwbs. Two, on Earth we still have people willing to do crap jobs, but people are terrible at working in space. That gives huge extra incentives to cut them out of direct, real-time involvement in the production cycle in space manufacturing.

Imagine autonomous robots that could quarry stone, transport it to a building site, prepare the site, and arrange the stone into a castle (or residential city blocks built of stone, like Europeans once used to make). And imagine they could do this quickly with minimal human guidance, and very low energy cost. Imagine even that much of the stone could be sourced at the building site, a byproduct of blasting the site level. Would we built a castle, or even a roomy apartment, for everybody who needs a place to live? No way. Politics would block it. Just maybe, if we started a city from scratch in some now-uninhabited place – something like Brasilia – we could get away with it. I fantasize about this sometimes.

The energy costs, let alone the risks of deorbiting massive volumes of dense material, pretty much rules out space as a source of this material for Earth. Space manufacturing makes most economic sense when the material is used in situ Only very high value or unique materials and products are worth sourcing in space and returning to Earth, at least in the early stages to get a business started under conventional economics. Historically, almost every product idea that has been proposed to capitalize on zero-g manufacturing conditions has been obsoleted by manufacturing developments on Earth. But seredipity might change that.

I know I’m diverging from the topic at hand a little but I just wanted to add the trivial addition that while visions of interplanetary expansion are interesting to me personally, it’s a side show to the massive social upheavals and inequities “we” will initially have to deal with in the posited new economy. Whether or not ai leads longer term to a new form of societal fractioning and or some sort of post human world (should the scenarios of cybernetic integration come to pass with its potentially radical reset of individual and social priorities), initally a new sort of extreme stratification will arise. Regulation and monitoring of both ai and the human power dynamic will be vital if we aspire to mitigate the risks to the health and stability of our society. Off topic off.

Deployment of AI and robots on Earth is a far more immediate social issue and is being widely discussed already. I suspect that this problem will either be solved, or not, before solar system scale asteroid mining reaches significant scale to Earth’s economy. Let’s hope our civilization solves the problem that benefits everyone, rather than a few plutocrat overlords.

1. We foul our worksites here. How do we prevent a cloud of dust and grit and rocks from being generated and maybe making the regions unusable? (Hopefully slowly) growing regions.

2. I guess if the AIs are usually resourceful enough to make the process work one can afford to abandon the few that don’t make it work rather than having people on site.

3. No government should allow that much activity with such potential to harm us without safeguards in place and those will be expensive safeguards.

Water extraction would release less material than a comet outgassing. Mineral extraction would immediately result in dust remaining in the asteroid’s orbit and would slowly be pushed outwards by solar radiation. All those comets over billions of years haven’t polluted the solar system very much, so I don’t think this is a real issue. This is not like mining on Earth. And don’t forget, space is big, really big. ;)

1. The surface gravity for a large metal asteroid like 16 Psyche is around 30 milliG, with an escape velocity of 140 m/s. A smaller metal asteroid like 1986 DA would have an escape velocity of 2 m/s. We’d want a tent or shield around grinding machines to keep fast moving stuff from flying off into space and creating a hazard. Then once the grinding stops, wait for about five seconds for all the dust to settle before opening the doorway.

2. I like thinking of the software, the computer hardware, and the mechanical hardware as three separate kinds of things, rather than lumping it all together as “an AI”. If the mechanical hardware is designed for manufacturability and repairability, then software can be written to repair or replace the broken parts. And once the software is written for that particular failure, it can be re-used again and again. We don’t expect the software to figure out the repair program all on its own, we expect the repair program will be written by someone on Earth, initially debugged by simulation.

Welcome back Paul. What a great piece with which to welcome us all back – thank you!

My pleasure, David. Alex did a terrific job on this piece — it’s certainly provoking plenty of discussion!

Oh, forgive me, thank you too Alex.

I am utterly convinced that an asteroid industrial age is upon us all – and that the earth-moon-NEA economy will expand into a huge enterprise that dwarfs the Earth’s economy in a few short generations.

Unfortunately, I am not convinced that it will be a peaceful, adventurous, and primarily a techno-industrial focussed endeavour. With huge resources, strategic space positioning, and creating that first platform to post-‘small crew’ space inhabitation/ colonization as early goals, the main political entities will trip over themselves to establish first claims. Swarms of craft will flock and seek and descend as if on prey. It would be interesting to know if contingency plans for refereeing the inevitable scrum have been discussed at an international level. Have the top 100 asteroid ‘potentials’ been defined in the sense of accessibility and value? Has there been a build-up of exploiter craft research and testing outside of the known private firms and public institutions? Has first claim protocol been established? The key, of course, is the situation once the low hanging fruit have been spoken for and a type of undeveloped claim scarcity sets in. That all being said, I am confident that a peaceful orbital and pan-orbital infrastructure will eventually be established so that a human presence can start to fan out in the 5-day to 5-week work/ play/ learn/ live threshold. From there, with post-human biological technology and post-scarcity prevalent in the mid-22nd, so will the great diaspora start as space-industrial discards, asteroid fragments, and ad-hoc space ‘habitats’ head outward to mars orbit and beyond, only possible due to the great asteroid ‘rush’ of 2025 and the subsequent build-out of robot-AI pioneers.

You have a window to provide that, possibly very profitably. This is a “sell the miners shovels” business model that made some suppliers very wealthy.

Its nice to be an optimist about the so-far-nonexistent nature of AI , but try NOT to forget how a fine line divides optimism and foolhardy lack of responsibility for the future ….I dont mind risking my own life now and then for a good reason , but playing with AI without ANY prior knowledge about the actual risk involved , can best be compared to playing Russian Roulette with the future of mankind …. its very , very disturbing to experience the way any kind of demand for strict and non-trusting regulations of AI development has gone out of fashion , to put it mildly …it seems that blind faith in the naturally GOOD nature of AI has become an article of faith , a membershib card whithout which many doors will remain closed …..it seems that the optimists have closed the case , AI not guilty for lack of evidence ….but this is Insane as measured by any kind of Comon Sence , the burden of proof must lay with the defence of AI !

We agree with Elon Musk that unconstrained AI can be dangerous. Research in building a an AI with free will should be banned. We want our machines with AI to be obedient and useful, like the Mars rovers and self driving cars.

An obedient and useful AI will of course be Plan A , but what happens if (and this seems more realistic each day ) i turns out that the kind of independent GENERAL problem solving capability neccesary for increasingly complexs missions , can only be achieved by a increasing degree of ”free will ” in the self-learning capabilities of the AI ….who exactly is going to say stop if the AI system starts improving its performance drasticaly when allowed to use a self-learning-algorithm of its own design , or more exactly an algorithm that has been developed using same AI as a software developing tool ? (thereby closing the causality loop ) .. who exactly is going to change direction just when a real breakthrough happens ? …. probably not the same people who have struggled to make the thing work for a decade !

“Research in building a an AI with free will should be banned.”

Add that to the laws prohibiting murder and drug trafficking. I’m sure we’ll solve the AI research ‘problem’ just as effectively. In other words it’ll happen regardless. Doing the research in the open and in a controlled fashion, but only when we approach the goal (in the unpredictable future), is more sensible than attempting to ban what cannot be banned.

I think Nick Bostrom, for one, would disagree with you about the optimists having closed the case. There is certainly a lot of dissing of AI pessimists in some AI FB groups, often arguing from authority, but groups less close to workbench are more concerned.

I suspect regulations will not be proactive, but retroactive, in response to some unexpected problem. The use of robots by the military will likely expose the “canary in the coal mine” with respect to harming people. If you want a nice scary story of malevolent machines, P K Dick’s “Second Variety” is a good start.

People will become used to space habitats.

Don’t forget that most of the earliest Europeans who came to America starved, froze, or died of disease. Some perished fighting the Indians. Nevertheless they persisted.

In space habitats there will be no native peoples displaced or killed, no diseases. Climate will be controlled.

The Earth isn’t going to perish any time soon but it will never be the same as it has been; habitats can approximate it, though. In fact, if humans hadn’t appeared the Earth today still wouldn’t be the same as 10 million years ago.

We have to expand to survive and prosper.

It would be wonderful to many kinds of habitats of many different sizes. One habitat that catches my imagination is an Earth – Mars cycler. It would be big enough to have artificial gravity, roomy enough to grow crops, and designed to have a closed ecosystem. The structure and pressure hulls could all be built and assembed robotically, then humans could move in and outfit the interior. And we already have a name for the first one; it would be called the Oasis A. Of course, we really mean to call it the Oasis Aldrin.

I think your suggestion that research use might be more profitable at the start is interesting (usually I hear that water is probably the first thing of value that will be gotten, with some patents for developing the technology on the way)–what sort of uses do you envision?

? JAXA-Hayabusa to asteroid Itokawa, launched 2003, returned <1 milligram in 2010. It was a $250M mission.

? JAXA-Hayabusa 2 to asteroid Ryugu, launched 2014, returns in 2020. It's a $400M mission.

? NASA OSIRIS-REX to asteroid Bennu launched 2016, returns 100 g. to 2 kg in 2023. It's a $950M mission.

? NASA Discovery mission to asteroid 16 Psyche launches 2022, to orbit, map, and measure. It is not a return mission, but is estimated to be a $600M mission.

This shows that governments are willing to spend hundreds of millions of dollars for a few kilograms of asteroid material. If we can go out to 16 Psyche and return a few kilograms of asteroid material, it may be possible to sell it to government sponsored researchers for $50M to $100M. If that covers our costs, we'd be happy.

If I remember properly, the moon-bootstrap approach was actually based on ever increasing human controllers back on Earth until the *assumption* that one day true self-rep AI robotics would arrive to take over on the moon. But the fact is while AI is getting faster and better, we don’t *know* that is going to happen, and I question the economics of an ever increasing army of ground controllers trying to efficiently manufacture stuff on the moon with a few seconds relay delay.

If we really want to bootstrap the solar system, shouldn’t we send a few thousand people up to both the moon and Mars?

Mars is especially interesting as it can quickly be partially terraformed to much more livable than it is now. The initial city of a million people that might start terraforming Mars will only take 770 Space X BFR’s. (100 people each * 10,000 flights with 13 round trips to Mars, leaving the ship there on the last trip.) They’d start by cooking the planet up with super-greenhouse gases, which within 100 years would give them blue skies, blue oceans, rain, protection from space radiation, and walking on the surface in normal clothes and a breather mask. Details here: https://www.universetoday.com/9730/zubrin-on-terraforming-mars/

When enough people are there, they could build a space tether out to Phobos which would open up the rest of the solar system for harvesting asteroids and other materials.

http://hopsblog-hop.blogspot.com.au/2015/06/phobos-panama-canal-of-inner-solar.html

I don’t know about “running out of controllers”. Expansion beyond the moon to the asteroids did assume far more autonomy of the robots.

Nothing in this scenario precludes people from actively participating in this space economy. However, the industrial expansion on Earth was about substituting machines for human muscles. There is a current angst that AI will replace human brains, eliminating humans from the means of production. It may not happen, but the point is that cognitive machines will replace some human functions, and that as the costs of humans in space are far higher than machines, intelligent machines are perhaps the economic choice for space manufacturing.

We don’t actually need our machines to have an intelligence level above that of smart insects for a self-reproducing factory economy. It isn’t as though they’d have to invent new technologies in order to mine asteroids and build more machines.

It’s my hope that AI will eventually come to mean “Amplified” rather than “Artificial” Intelligence. Let’s keep the free will for ourselves, and just let the machines expand our capabilities. There’s very little in the way of jobs for autonomous machines that actually requires human level intelligence, in order to vastly expand our economy. The design work that really does require intelligence could be done by artificially augmented humans.

The desire for true human level and above artificial consequence amounts to a desire for a kind of technological “genie”, that can do for us complex tasks that we don’t want to do, or aren’t capable of.

Genie stories, outside of Disney, don’t usually end well.

Doesn’t this analysis assume that the potential size/growth of an economy is determined by the quantity of available natural resources? This is clearly not true. See, for exampke, the resource curse: “The resource curse, also known as the paradox of plenty, refers to the paradox that countries with an abundance of natural resources (like fossil fuels and certain minerals), tend to have less economic growth, less democracy, and worse development outcomes than countries with fewer natural resources.” Wikipedia

“the resource curse” concerns how nations develop their human assets. Educated, post-industrial, societies do not have that problem. What they do have is a limit on exploitable, physical resources that puts limits to human expansion, effectively a Malthusian limit. If space to grow/manufacture food and build living spaces is unlimited, human populations can expand to fill that space. That is the basic argument behind K1 civs maximally utilizing their star’s energy by building Dyson spheres/swarms. As the size of an economy grows in response to population size and productivity gains, a vast expansion of living space and resources will create an “unbounded” economy. In practice, at 2-3% growth rates, a K1 civ economy might fully utilize the resources of a galaxy within a millennium (which is impossible with c as an expansion rate limitation), and further millenium to fill the universe. So economies cannot grow forever, at least not physically. Having said that, there is a huge expansion possible by exploiting the physical and energy resources of our solar system, and we would need a large expansion to allow for the manufacture and launching of starship fleets.

“and we would need a large expansion to allow for the manufacture and launching of starship fleets.”

The key point here, I think, is that we need the economy to expand dramatically faster than population for a while, to afford starship fleets.

You could imagine a future without autofactories, where mankind conquers the entire solar system based on ordinary, human labor dependent production, with the economy growing together with population. And eventually we hit the economic limits of the solar system, without ever having had the *surplus* necessary to afford star ships. Which are by anybody’s standards extravagant, based on any physics we know.

With the autofactories, instead what happens is that the size of the economy takes off on an exponential growth, *uncoupled from population*, until it hits real or artificially imposed limits. But that growth would be enormously faster than population growth until it hit those limits, and so we’d end up with the surplus economic capacity to do extravagant things like colonizing the stars.

Even in the no autofactory scenario we probably end up colonizing the stars via diffusion out through the Ort cloud, but on a much slower basis.

The “resource curse” is what you get when you have an authoritarian/totalitarian inclined government, which substitutes a very profitable extraction industry for taxation. The government then deliberately suppresses the rest of the economy, because by doing so it eliminates alternate power centers, and secures it’s own hold on power.

In the case of some particularly poor countries, the “resource” in question is foreign aid…

You don’t get the “curse” unless the industry in question ends up nationalized, providing the government with a source of income that doesn’t require a healthy economy.

“The eventual goal of robot miners and fabricators producing commodities and goods at a fraction of today’s prices, via massive supply expansion, may face some short term obstacles.”

I’ll believe that when all the miners on earth are put out of business. ;-) I mean, I hope we can enter a post-scarcity, robot driven, abundant UBI economy. But it’s just that, a sci-fi hope. I’m all for robot-taxi’s and things like that, but my understanding of mining, refining, smelting, manufacturing components with machine tools, etc etc etc is that it’s large, bulky, human driven and requires lots of pizza, pies, and beer to run! The goal is fantastic, and every advance in minaturising machine tools, new mining and refining and smelting processes, etc makes a Mars base more viable and fits more kit into a smaller place on a Space X rocket. Great! But it’s time to acknowledge that there’s a whole spectrum between where we are now and firing one self-rep at an asteroid and having a whole industrial base blossom without any human input. If that could happen in space, imagine what it could do here on earth!? But any step *towards* that goal is commendable and will help Elon Musk conquer Mars that much easier.

Nobody is arguing that this happens near instantaneously. It is also well known that short term predictions tend to be optimistic, but long term ones, pessimistic.

Knowledge of the history of industrial expansion on Earth across nations is instructive concerning the economic replacement of humans by machines. Space manufacturing increases the costs of humans relative to machines, so we should expect machines to be used wherever they can, and humans as sparingly as possible.

PS: In other words, “Short term obstacles”, like the technology hasn’t been invented yet, and we don’t *know* if the technology can ever be invented? ;-)

I see no obvious technological issues in developing robot miners. Those mining close proximity NEAs can be handled by teleoperation, and AI increasingly used as these miners move outwards into deep space. Increasing autonomy will happen, and perhaps faster than we expect. Self-driving cars are already on the roads, and will be legal to deploy in California in 2018! Think about that. Would you have predicted that just a decade ago?

As someone with a PhD in Earth Observation, I doubt that it can be a real fundraiser in the whole project. We live in the era of the data deluge, and the most innovative EO companies are not so much selling pictures but rather selling services: some algorithm that extracts future agricultural production or fuel supplies inside storage tanks from entire images and sell that number to the business intelligence types, a.k.a. Wall Street. NGA does subsidize the US EO industry by having bulk buys of all earth imagery acquired by them. Academia most often cannot really afford satellite images, beyond a few in whatever the grant allows. Business intelligence is the new game, guess this year’s Walmart’s sales by measuring how many cars are parked in the parking lot compared to last year. Still it is a niche market and there are several high res cubesat providers all ready, on top the more traditional consolidated at DigitalGlobe. Private astronomical observations might be market, charging astronomers for observations the way that say Keck does. Still, I see slim pickings. Good luck though

That is a very good point about the value of pics vs analysis. Farmers want actionable information about their crops which imaging does not provide. This is a field rich in targets for machine learning to provide real value. I suspect that ML will also be useful for analyzing asteroid targets from Earth and locating ores by prospecting probes. Simpler computational techniques can be used to locate asteroids more effectively as this article notes.

[I don’t think it is legal anymore to use EO images to get an edge on stock investing, as the data is not considered public.]

American farmers, at least those in California and the Midwest, do and are willing pay money to get images on the status of their crops. Some of the big CA wineries actually have entire GIS/RS analysis groups employed, poring over mostly aerial imagery to manage more efficiently individual bushes. There are several business intelligence companies using RS data to do what I described, I remember a feature lecture in an ASPRS conference about using DigitalGlobe imagery to do what is described, and they are not the only ones. There was an article today on SpaceNews about a startup using radar imagery to measure fuel tanks. I keep myself appraised of the latest developments in RS, as much as my job allows, and so far I have not heard anyone mention legality. Satellite imagery is considered a legal source of data rather than proprietary data.

I was wrong about the legality. Satellite data is considered public information and therefore not legally “insider trading”, even though it does violate the rule about all investors having access to the same information, as only large investors, like hedge funds can afford to buy and use the data.

We agree that automated image analysis is a hot area right now, and startup costs would be similar to a software startup, with little capital needed. We don’t have the background for that area, though.

For the space astronomy market, we’d be unique. We’ll have a number of specialty filters, an image intensified EMCCD camera, and lots of on-board computing resources, so we should be able to implement synthetic tracking and have other capabilities for amateur and professional astronomers. It will be a small market, though.

We have looked at the EO market, and are targeting 1 meter GSD panchromatic and mutispectral. We are also putting in a hyperspectral camera. We don’t know of any cubesat with these capabilities. The EO market is crowded, but we think we can compete well on cost/performance. And the technologies we are using for the cubesat based space telescope will also provide big cost advantages for 30 cm resolution EO satellites.

Mining and manufacturing do not require intelligence. A lot of intelligence is needed to design the processes, but that will be done on Earth. Their execution is repetitive, dumb labor that computer technology from the 80s is sufficient to control.

Thus, the statement that “self-replication requires AI” is patently false. It can also be easily falsified by invoking the humble bacterium.

Tell that to prospectors. In manufacturing even after the production line is built, intelligence is still needed to deploy and manage it effectively, even if that intelligence is fairly rudimentary in some cases. QC needs some intelligence to manage it, as does changing out parts that wear, fixing breakdowns, managing inventory, and a host of other problems in a non-controllable environment.

Today, machine self-replication is very different from biological replication. I am not aware of any schemes that use some form of biomimetics in this regard, other than the use of many small, standard parts that are used to construct machines, rather like the cellular model of multi-cellular organisms. Having said that, in principle, self-replication doesn’t require high intelligence. But bear in mind that even bacteria have cellular systems that have “baked in” knowledge from their genes and can learn to adapt to changing conditions, which is intelligence, even if very minimal against the scale of humans.

I was talking about mining and manufacturing, not prospecting.

Prospecting requires some more intelligence, albeit I believe that even that can be achieved with very simple, repetitive heuristics. Like: Select next asteroid to target, plot course towards it, scan it with instruments, make yes/no decision based on elemental composition, call in the mining robots (if yes), repeat. Each of these steps in turn seem amenable to automation without human level intelligence. Many insects perform similar or more complex tasks to acquire food to survive. Spiders, say.

We think that a small amount of AI technology would be useful to minimize the amount of human interaction, similar to the level of intelligence of a self driving car. If something unexpected happened, one simple policy would be to stop the affected machines, send telemetry back to Earth, and wait for new instructions. This is how the Mars rovers are managed.

Yes, to the extent that AI is available, it can be very useful. My squabble is with those who say that “advanced AI” (meaning what we do not yet have) or “human level AI” or “self awareness” are necessary to build self-replicating systems. None of them are, and life on Earth gives us copious and obvious proof of that.

Ooops, I misstated somewhat. Of course, to design and build these systems, you do need human level intelligence. I meant the systems themselves do not need to possess any of these capabilities.

Another possibility might be asteroidal gold mining. The unique thing about gold is that its main use – as a store of monetary value – does not require its physical presence at the point of application; it can be held anywhere, as long as it is secure. But gold bullion in space is already safer than in any bank vault on Earth (thieves can’t breathe vacuum, and the laws of celestial mechanics can’t be bribed), so there is no reason for it to ever leave the asteroid on which it was mined. Purchasers of asteroidal gold might even be willing to pay an ongoing annual fee, for the secure storage.

The practicality of mining precious metals from asteroid metal really depends on its concentration, and that varies. For instance, for the Hoba metal meteorite, iron, nickel, and cobalt make up 99.8% of the metal. Platinum is number 4, at 80 ppm, then osmium at 40 ppm. Rhenium and palladium are numbers 9 and 10, at 5 ppm each. For this meteorite, the gold concentration is below 5 ppm. There could be asteroids with different concentrations of precious metals, but likely still measured in parts per million. Prospecting asteroids and locations on an asteroid for a particular high concentration precious metal is going to be expensive, but we might get lucky right away.

You’d have to process a lot of asteroid metal to obtain the precious metals dissolved in the metal alloy. That’s why we are concentrating on making use of the raw metal first, in order to make pipes, joints, tanks, valves, and eventually a chemical processing plant to extract the precious metals.

Platinum is the best bet here, it being the most common in asteroids, and also the most expensive on Earth. You’d have to be careful to not overproduce too fast, and the opportunity would be of limited duration as the price goes down.

Also, platinum is a very sturdy metal, if you reenter a lump of it at the right angle, most of it would make it to the surface to be picked up. If they allowed you to do that, it would be a very cheap way to bring the winnings home.

By that logic we could use the gold that’s in the Earth’s core. Nobody can steal that, right? The problem is that it does not really belong to you if there is not a way to get it to you, and the value is always diminished by the cost of actually getting it. That’s why the gold that’s still in the Earth is worthless until someone goes to the trouble of mining it.

Gold is suboptimal for several reasons, not the least of it that its already tenuous claim as a “store of monetary value” will be further diminished if it became available in substantial amounts from a new, inexhaustible source. It’s value would plummet faster than that of, say, platinum, because it has fewer actual uses that could stave off loss of value by expanding demand.

The value of gold depends on supply in the market, not the amount in storage. As gold has been effectively decoupled as the backing for money, Goldfinger’s plan to irradiate the gold in Fort Knox to make it undeliverable would no longer work. The most famous example of this model is the diamond business.

You could mine and store gold in space, delivering just enough to keep the price high. However, I seriously doubt this would work as a business model using current technology, current gold prices, and potential supply from storage and artifacts in circulation.