The advantages of a space elevator have been percolating through the aerospace community for quite some time, particularly boosted by Arthur C. Clarke’s novel The Fountains of Paradise (1979). The challenge is to create the kind of material that could make such a structure possible. Today, long-time Centauri Dreams reader Adam Kiil tackles the question with his analysis of a new concept in producing graphene, one which could allow us to create the extraordinarily strong cables needed. Adam is a satellite image analyst located in Perth, Australia. While he has nursed a long-time interest in advanced materials and their applications, he also describes himself as a passionate advocate for space exploration and an amateur astronomer. Today he invites readers to imagine a new era of space travel enabled by technologies that literally reach from Earth to the sky.

by Adam Kiil

In the quiet predawn hours, a spider spins its web, threading together a marvel of biological engineering: strands that are lightweight, elastic, and capable of absorbing tremendous energy before failing. This isn’t just nature’s artistry; it’s a lesson in hierarchical design, where proteins self-assemble into beta-pleated sheets and amorphous regions, creating a material tougher than Kevlar — able to dissipate impacts like a shock absorber — while outperforming steel in strength-to-weight ratio, though falling short of Kevlar’s raw tensile strength.

As we gaze upward toward the stars, dreaming of bridges to orbit, such bio-inspired ingenuity beckons. Could we mimic this to construct a space elevator tether, a ribbon stretching 100,000 kilometers from Earth’s equator to geostationary orbit and beyond? The demands are staggering: a material with a specific strength exceeding 50 GPa·cm³/g to support its own weight against gravity’s pull, all while withstanding radiation, micrometeorites, and immense tensile stresses. [GPa is a reference to gigapascals, the units used to measure tensile strength at high pressures and stresses. Thus GPa·cm³/g represents the ratio of strength to density].

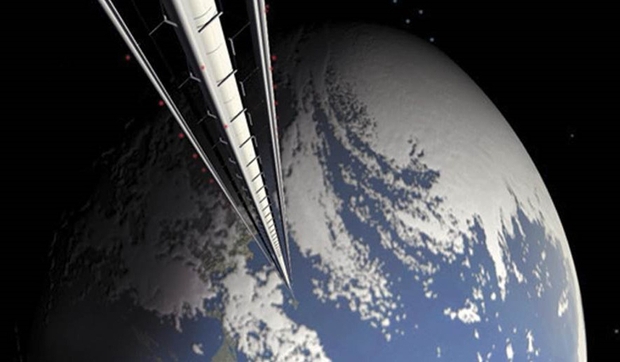

Image: A space elevator is a revolutionary transportation system designed to connect Earth’s surface to geostationary orbit and beyond, utilizing a strong, lightweight cable – potentially made of graphene due to its extraordinary tensile strength and low density—anchored to an equatorial base station and extending tens of thousands of kilometers to a counterweight in space. This megastructure would enable low-cost, efficient transport of payloads and people into orbit, leveraging a climber mechanism that ascends the cable, potentially transforming space access by reducing reliance on traditional rocket launches. Credit: Pat Rawlings/NASA.

Enter a recent breakthrough in graphene production from professor Chris Sorensen at Kansas State University and Vancouver-based HydroGraph Clean Power, whose detonation synthesis yields pristine, fractal, and reactive graphene — potentially a key ingredient in weaving this cosmic thread.

But this alone may not suffice; we must think from first principles, exploring uncharted solutions to assemble nanoscale wonders into macroscale might.

Graphene’s Promise and Perils: The Historical Context

Graphene, that atomic-thin honeycomb of carbon, tantalizes with its theoretical tensile strength of 130 GPa and density of 2.2 g/cm³, yielding a specific strength around 59 GPa·cm³/g—right on the cusp of space elevator viability.

Yet, production has long been the bottleneck. Chemical vapor deposition churns out high-quality but limited sheets; mechanical exfoliation delivers impure, aggregated flakes. These yield composites where graphene platelets, bound weakly by van der Waals forces (mere 0.1-1 GPa), slip under strain, like loose pages in a book. For a tether, we need seamless load transfer, hierarchical reinforcement, and defect minimization—echoing the energy-dissipating nanocrystals in spider silk’s protein matrix.

Sorensen’s Detonation Concept: Fractal and Reactive Graphene

Chris Sorensen’s innovation at HydroGraph Clean Power flips the script. Using a controlled detonation of acetylene and oxygen in a sealed chamber, his team produces graphene with over 99.8% purity, fractal morphology, and tunable reactivity—all at scale, with zero waste and low emissions.

The fractal form — branched, snowflake-like platelets with 200 m²/g surface area — enhances interlocking, outperforming traditional graphene by 10-100 times in composites, but crucially, these gains shine at ultra-low loadings (0.001%) and under modest stresses, not yet the gigapascal realms of a space elevator.

Reactive variants add edge functional groups like carboxylic acids (COOH), enabling covalent bonding—yet, note that simple condensation reactions here yield strengths akin to polymer chains (1-5 GPa), not the in-plane prowess of graphene’s sp² lattice.This fractal graphene could form a foundational scaffold, reconfigurable into aligned structures that mimic bone’s porosity or silk’s hierarchy. Earthly spin-offs abound: tougher concrete, sensitive sensors, efficient batteries. But for the stars, we must bridge the gap from nanoplatelets to kilometer-long cables.

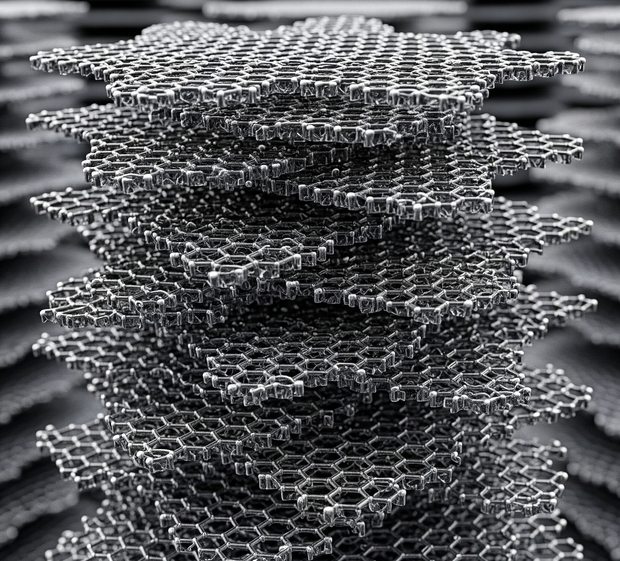

Image: Conceptual view of Hydrographs’ turbostratic, 50nm nanoplatelets, 99.8% pure carbon, sp2 bonded graphene. Credit: Adam Kiil.

From First Principles: Many Paths to a Cosmic Thread

To transcend these limits, let’s reason from fundamentals. A space elevator tether must maximize tensile strength while minimizing density and defects, distributing stress across scales like spider silk’s beta-sheets (crystalline strength) embedded in an extensible amorphous matrix.

Graphene’s strength derives from its delocalized electrons in a defect-free lattice; any assembly must preserve this while forging inter-platelet bonds rivaling intra-platelet ones. Current methods fall short, so here are myriad speculative solutions, drawn from physics, chemistry, and biology—some extant, others nascent or hypothetical, demanding innovation:

- Edge-Fusion via Plasma or Laser Annealing: Functionalize edges with hydrogen or halogens, then use plasma arcs or femtosecond lasers to fuse platelets into seamless, extended sheets or ribbons, healing defects to approach single-crystal continuity. This could yield tensile strengths nearing 100 GPa by eliminating weak interfaces.

- Supramolecular Self-Assembly in Liquid Crystals: Disperse fractal graphene in nematic solvents, applying shear or electric fields to align platelets into helical fibrils, stabilized by pi-pi stacking and hydrogen bonding. Inspired by silk’s pH-induced assembly, this bottom-up approach might create defect-tolerant bundles with built-in energy dissipation.

- Bio-Templating with Engineered Proteins: Design peptides (via AI like AlphaFold) that bind graphene edges, mimicking silk spidroins’ repetitive motifs to fold platelets into hierarchical nanocrystals. Extrude through microfluidic spinnerets, acidifying to trigger beta-sheet formation, embedding graphene in a tough, elastic matrix.

- Covalent Cross-Linking with Boron or Nitrogen Dopants: Introduce boron atoms during detonation to create sp³ bridges between platelets, forming diamond-like nodes in a graphene network. This could boost shear strength to 10-20 GPa without sacrificing tensile properties, verified by molecular dynamics.

- Electrospinning with Magnetic Alignment: Mix reactive graphene in a polymer dope, electrospin under magnetic fields to orient platelets, then pyrolyze the polymer, leaving aligned, sintered graphene fibers. Enhancements: Add ultrasonic waves for dynamic packing, targeting <1 defect per 100 nm².

- Hierarchical Bundling via 3D Printing: Nanoscale print graphene inks layer-by-layer, using click chemistry (e.g., thiol-ene) for instant cross-links. Scale up to micro-bundles, then macro-cables, tapering density like a tree trunk to root.

- Dynamic Compression and Sintering: Apply gigapascal pressures in a diamond anvil cell, combined with heat, to induce partial sp²-to-sp³ transitions at overlaps, creating hybrid structures akin to lonsdaleite—ultra-hard yet flexible.

- Biomineralization Analogs: Introduce calcium or silica ions to reactive groups, mineralizing interfaces like nacre, adding compressive strength and crack deflection.

- AI-Optimized Hybrid Composites: Simulate (via quantum computing) blends of fractal graphene with silk-mimetic polymers or boron nitride, optimizing ratios for 90% tensile efficiency. Fabricate via wet-spinning, testing at centimeter scales.

These aren’t exhaustive; hybrids abound—e.g., combining bio-templating with laser fusion. Each target’s aim: moving beyond low-load enhancements and polymer-like bonds to harness graphene’s full lattice strength.

Weaving and Laminating: Practical Steps Forward

Drawing from these, a viable process might start with a high-solids dispersion of reactive fractal graphene, extruded via wet-spinning into aligned fibers, where optimized cross-linkers (not mere condensations) ensure graphene-dominant strength. Stack into nacre-like laminates, using hot isostatic pressing (5-20 GPa) to forge sp³ bonds, elevating shear (and thus overall tensile) resilience to 10-20 GPa. Taper the structure: thick at the base for 7 GPa stresses, thinning upward.

Scaling leverages HydroGraph’s modular reactors, producing tonnage graphene for kilometer segments.

Join via overlap lamination, braid for redundancy, deploy from orbit. Prototypes must demonstrate cohesive failure, >90% load transfer, via nanoindentation.

A Bridge to the Cosmos

Sorensen’s detonation-born graphene, fractal and reactive, ignites possibility. Yet, as spider silk teaches, true mastery lies in hierarchy and adaptation.

Success means a tether with inter-platelet bond strength nearing single-crystal graphene (>100 GPa), verified by nanoindentation or pull-out tests, with >90% tensile transfer efficiency. Centimetre-scale prototypes should show minimal defects (<1 per 100 nm² via TEM), failing cohesively, not delaminating, like a spider’s web holding under a gale. The full tether, massing under 500 tonnes, could be deployed from orbit, a lifeline to the cosmos. This graphene tether embodies our ‘sea-longing,’ a bridge to the stars woven from carbon’s hexagons, inspired by nature’s spinners and builders.

By innovating from first principles—fusing, assembling, templating—we edge closer to stitching the stars. This isn’t mere materials science; it’s the warp and weft of humanity’s interstellar tapestry, a web to catch the dreams of Centauri and beyond.

If you are so bullish, start a company.

Andrew, your challenge is well-taken : HydroGraph is already scaling fractal and reactive graphene production, aiming for 1000+ tonnage outputs within a few years. Their focus isn’t yet a space elevator but spans composites and coatings, with sensors, and energy storage coming later (once cash-flow etc is established). Starting a dedicated space elevator venture would be tantalizing, but the material challenge goes, far beyond commercial scales. Novel approaches and a driven civilization might close this gap, but they’re lab-scale dreams for now. A company/country would need cross-disciplinary R&D (materials, aerospace, robotics) and massive capital to prototype centimeter-scale ribbons with >90% load transfer efficiency.

We’ll have to aim for more, at least 10x the strength and possibly far more. This is a large vulnerable target, whether by intent or accident. No matter the material availability, I expect quite a challenge in developing a viable business case. We might do as well by awaiting the invention of cavorite.

Am I too negative? Perhaps. Nevertheless I see no path forward or even a need to pursue an elevator. It looks good as a device in fiction, but in reality? I wonder.

Ron, skepticism is very well founded. The strength requirement is indeed daunting: a tether needs 50 GPa·cm³/g specific strength to bear its own weight over 100,000 km, and graphene’s theoretical 59 GPa·cm³/g is tantalizingly close but limited by inter-platelet slippage (0.1-1 GPa van der Waals in composites). A 10x boost over current bonds (e.g., ~1-5 GPa from amide linkages) demands radical innovation—perhaps plasma-fused seamless sheets or AI-optimized protein scaffolds mimicking spider silk’s beta-sheet hierarchy, which achieves ~1.5 GPa tensile with ~350 MJ/m³ toughness. Vulnerability is a real concern; cosmic rays and micrometeorites could degrade even graphene’s sp² lattice, necessitating nacre-like laminates or bio-mineralized coatings for crack deflection. The business case is trickier, SpaceX is already well on the way to lowering launch-costs to affordable for all.

Sounds promising, but let’s see if they can live up to the promises. I’ve seen many graphene (and other carbon allotrope) proposals over the years…

Wariness is warranted as graphene has been the poster child of hype since its Nobel-winning discovery.

Past proposals, from CVD-grown sheets to carbon nanotube yarns, often stalled at lab scale or faltered under real-world loads due to defects or weak interfaces (0.1-1 GPa van der Waals slippage).

HydroGraph’s detonation synthesis stands out for its scalability (tonnage production, >99.8% purity) and fractal morphology, boosting composite performance at low loadings (0.001%), though as you imply, these gains are so far modest (MPa range, not GPa). For a space elevator’s ~50 GPa·cm³/g requirement, we need to transcend these limits.. perhaps via edge-to-edge covalent stitching (e.g., boron-induced sp³ nodes) or bio-templated fibers emulating spider silk’s hierarchical toughness.

The proof’s in prototyping: centimeter-scale ribbons with 90% tensile transfer, could silence doubts.

HydroGraph’s not there yet, but their process’s scale & efficiency is a massive step beyond past promises.

What milestones would convince you the hype’s real this time?

IIUC, to gain the tensile strength needed, the graphene platelets need to be joined horizontally across the platelets with adjacent ones/stacks, to form a ribbon. The weak interplatelet bonds could be enhanced by either adding boron or bonding the platelets to proteins whose orientation is aligned in the direction of the ribbon, but also cross-linking (with disulphide bonds?) to keep the platelets stacked to enhance fracture resistance (between platelets that reduce sliding).

This all presumes that this manufacturing technique outperforms any other mass-scale graphene manufacture for light- or beamed sails (on the NASA roadmap) or carbon nanotube manufacture using similar techniques to ensure tubes bond to adjacent tubes.

If this is possible, it seems to me that manufacturing short (centimeter) length ribbons would prove the idea has merit. However, my guess is that most likely you will not get much improvement in strength over the binding molecular elements, i.e., the proteins. But that is just a guess, and creating strong ribbons by experiment is what is needed.

Even if the ribbons prove inadequate for a space elevator, they may be useful in other, less demanding applications, e.g.:

1. Cables for architectural and engineered structures.

2. Improving concrete resistance

3. Lighter bulletproof and penetration-proof shields

4. Stronger body panels on upmarket “supercars” and military vehicles.

Graphene has been posited as a sensor. Would this allow cheaper, multi-sensor applications in the same package? Graphene is an excellent electrical conductor, and in slightly twisted sheets, it forms superconductors. Would they be a good material for CPUs/GPUs?

If the platelets can be made to bond edge-to-edge, even without high tensile strength, they might solve the issue of creating monolayer sheets suitable for light, or beamed, sails. These would be near the ultimate low-areal-density sail material.

Anything bonded with proteins bothers me about how graphene platelets will degrade in the environment, especially as we know microplastics are an environmental issue. If used, proteins will degrade in a number of ways, releasing the graphene platelets, whether still in ribbons or not. How will they degrade in the environment? While diamonds can burn, we know they are highly resistant to degradation. We also know that carbon-rich biochar does not degrade readily and is used to amend soils. Where will graphene sit in this regard? What about near-pure graphene sheets/ribbons? What experiments have been done on pencil leads to determine how they degrade?

Just breed bigger spiders. (Sorry.)

Alex, that is the core of the challenge of a space elevator tether made from Hydrgraph’s graphene. Graphene’s 130 GPa tensile strength is useless if platelets slide at 0.1-1 GPa van der Waals interfaces.

That’s where horizontal bonding shines as the fix. Boron doping in a detonation process spikes sp³ nodes at edges, jacking shear to 10-20 GPa via electron tweaks (DFT calcs show ~15% bond energy boost). Pair that with silk-inspired proteins – AI-folded peptides mimicking beta-sheet cross-links (disulfide bonds at ~250 kJ/mol) and you get 90%+ load sharing, toughening it to silk’s 350 MJ/m³ without the brittleness. It’s like weaving a net that catches stress before cracks run wild.

For proof, centimetre ribbons are key: We’d spin in a scaled reactor, then hammer with nano-indentation and TEM to confirm 500°C, sp² bonds at 800 kJ/mol) are way stabler than biochar, but yes, once bonded and in ribbon form the effects are much more complicated.

There is an awful risk to be taken at a safety margin of 1…

Perhaps it would be better to have a cable anchored on the moon which dips deep into the earths gravity well. On this we put solar cell stations that send power to the moon and earth or anywhere in the solar system for that matter.

I’m sure once we are at the level on the Kardashev scale that we are starting these projects, we will find unforeseen innovative designs and concepts. The baseline design demands immense strength, but perhaps the real magic lies in hybrid materials and bio-inspired variants.

Nature’s webs aren’t rigid monoliths, they’re adaptive networks dissipating energy hierarchically.

Now what worries me is a little thing called the ITCZ

https://en.wikipedia.org/wiki/Intertropical_Convergence_Zone

Thunderstorms grow taller in the tropics—and icing loads need to be taken into consideration. Air France Flight 447 was lost due to icing of the pitot tubes—and an elevator car may have worse problems with ice fall than even Columbia had with that icy foam.

Perhaps where the Prime Meridian intersects the Equator (zero lat’ and long’) near Sao Tome is a bit more quiet–with the hump of Africa at least keeping things a bit calmer.

There will be lightning strikes.

Now what I would propose would be a bit wilder than a space elevator–two concepts in fact.

One would be a backspun asteroid fly-by rotorvator skyhook.

Many of these spacebergs are contact binaries. Your cables and some big bags could turn these into bolas–perhaps with tails.

Cables sliced through the Kursk, and may be of use with nickel-iron slugs.

A backspun bola would only need a few hundred miles of cables.

I would like to see that snag large payloads at sea.

These floating payloads would have solid rockets just to reduce strain on the carbon lines.

I could see items about as wide as an oil derrick yanked free of the Earth, with perhaps the counterweight being deposited down in exchange for asteroid mining HERE.

The second concept:

Instead of just one space elevator on vacuum worlds—perhaps two far apart.

Imagine they cross in the shape of an “X”

The tops would have immense statite sails.

Where the two lines cross–you would have a flying windlass that would have a third tether between the other two dangling down towards the surface.

Simply by having solar sails tack towards or away from one another—the intersection point rises–and lowers—the windlass lowering or raising payloads to the surface quickly.

No need to inchworm up a single tether on a trip that takes a week.

–publiusr

Hi Adam

Nice to see another Aussie (and another Adam) getting into a Space Innovation.

Graphene was my theoretical material when discussing a Solar-propelled 3I/ATLAS – as a theoretical exercise, mind you. Intriguingly a giant multi-layered ball of graphene is surprisingly effective at surviving a very high aero-capture entry speed for arriving at Jupiter.

Whether space-elevators are highly desirable for the Earth is one thing, but they can be surprisingly effective at accessing our Moon and other moons in the Solar System. A Sky-hook from Phobos to the top of the Martian atmosphere is also another option.

For full-scale reclamation projects, like the terraforming of Venus, then Space-Elevators will definitely be required. Multi-million tonne batches of hydrogen, launched from Uranus, will require heroic space elevator or rotovator systems.

I don’t understand the obsession with the common space elevator after known that other similar infrastructures, more versatile and convenient are available.

My favorite are orbital rings. A balanced two ring system (i like the configuration of an inner and outer rings) so the total forces make it maintain the orbital position while the outer layer maintains a fixed position related to the surface.

They can be build at any height with enough vacuum to avoid friction and regardless of the surface rotation of the body (extremely useful for small bodies like asteroids).

And they can work with very slow rotation bodies like Venus.

They take lots of infrastructure, BUT being realistic, a reliable space elevator would also require a lot.

And it’s a lot more compact. Ideal to travel “fast” in comparison with a space elevator.

Less material strength requirements.

Just… more complex. Probably best to build in other places before Earth, like the Moon or Ceres.

But.. yeah… they can beat space elevators in most characteristics and it doesn’t require materials outside of our current technology level.

Only LOTS of materials. I guess we should start making lots of IRSU on the moon and built it remotely.

Long term planning.

Isaac Arthur’s youtube channel has a great video about Orbital Rings (and a lot of crazy ideas).

But here the physics is solid and Orbital Rings and Space Elevators are at similar difficulty level.

OR require more materials and certain scale.

SE require better materials than currently available, and the scale will be needed in the future to make it practical and not just a demonstration concept.